Cleaning your chiller typically requires the manual labor of four employees and must be performed every night to ensure you meet stringent food processing safety standards. Sanitizing your chiller this way is labor intensive – but until recently manual cleaning was your only option. Now, there’s a better way to clean your chiller, and that’s with the automated Clean-In-Place solution from JBT.

By automating your cleaning process, you can reduce cleaning labor down to one employee who operates the cleaning system. No longer do you need multiple employees to complete this task.

One additional, very important benefit of automated cleaning is that it improves worker safety. Because workers no longer have the task of cleaning heavy equipment in confined spaces, you can eliminate human error and many of the associated accidents.

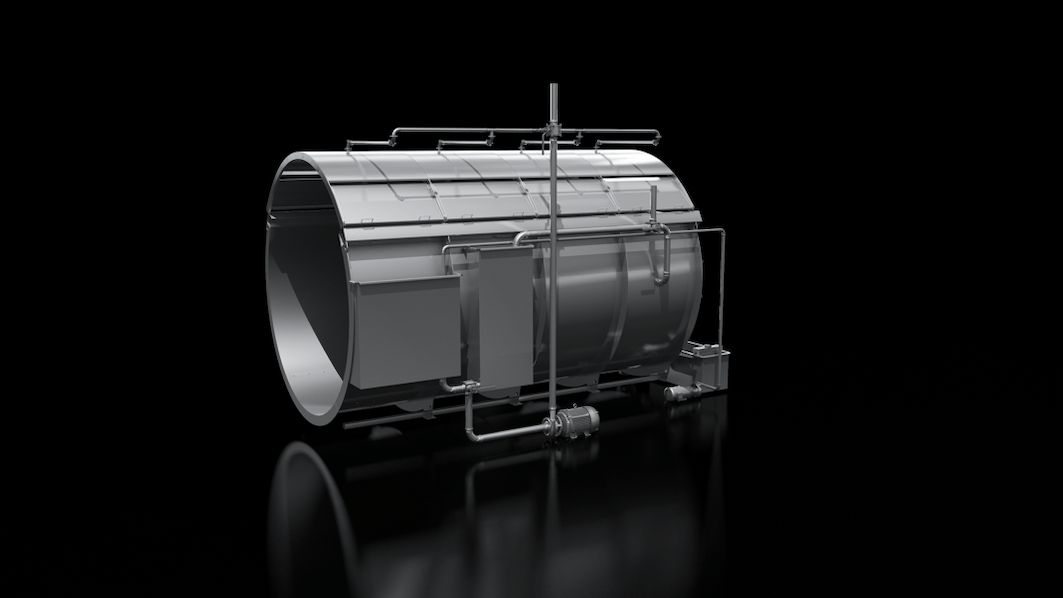

CIP technology for the JBT C.A.T. NEOCAT can improve worker safety and reduce labor costs

Recognizing the challenges of manual chiller cleaning, JBT has developed and patented Clean-In-Place technology to automate chiller cleaning. This system can reduce labor costs, enhance worker safety and even improve food safety.

In trial runs, Clean-In-Place was shown to be 100% effective in removing contamination. Clean-In-Place can be added to any existing JBT chiller – including the new C.A.T. NEOCAT Chiller.

If you’d like to learn more, about how Clean-In-Place can take your line to the next level, visit our product page or contact your JBT representative.