Interested in reducing false rejects and the need for rework on your fish processing line? JBT Innospexion’s cutting-edge fish bone detection X-ray technology offers a simple advantage – we detect bones that others cannot.

Worldwide, demand for fish and seafood is growing, while at the same time there is growing concern about pressure on fish stocks. In order to preserve profits in such an environment, there is a vital need for fish processors to maximize yield and minimize waste to get the most out of every piece of fish that passes down the line.

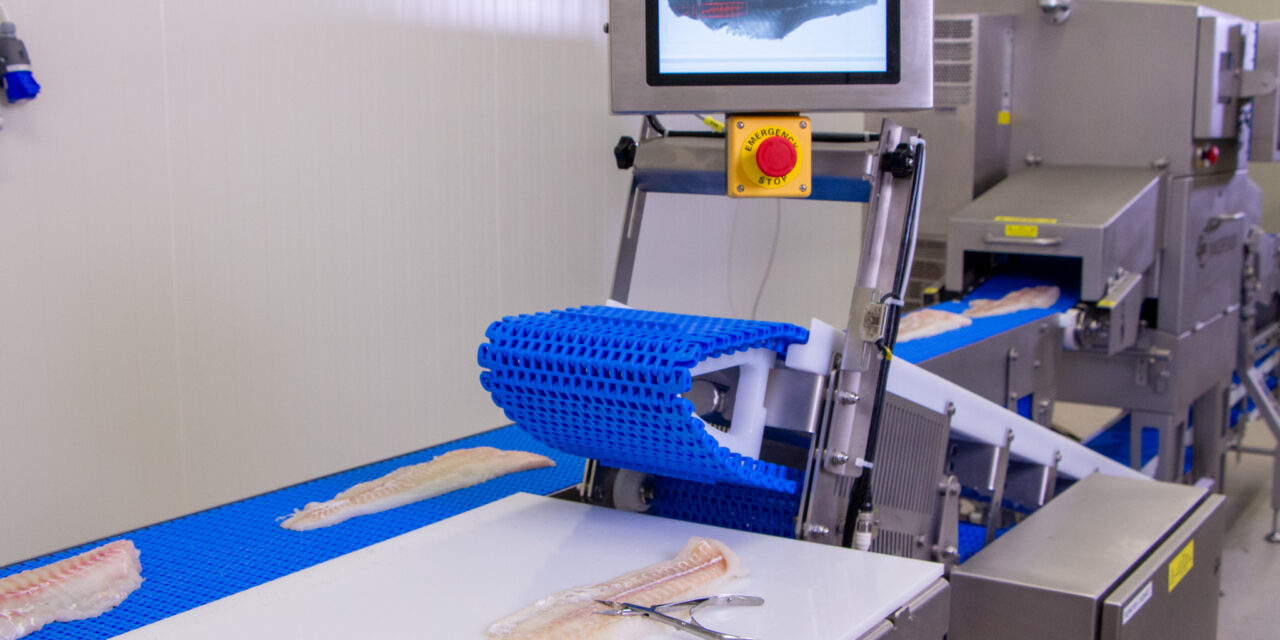

JBT Innospexion helps you improve yield, enhance product quality, and exceed customer expectations by using an advanced detection software and high-definition imaging for precise bone identification.

The unparalleled accuracy of the Innospexion system minimizes errors, resulting in reduced rework, significantly fewer false rejects, and maximized yield. The result? Improved efficiency and optimal productivity, providing a strong return on investment.

How does it work?

Building on over 20 years’ X-ray and algorithm experience, Innospexion uses Long Wave X-ray (LWX) technology to detect even small differences in thickness and density within fish that can go undetected with ordinary X-ray systems.

According to Dino Carbone, Global Product Manager for JBT XVision, the lightly-calcified nature of fish bones means they are often difficult to identify during a standard X-ray process.

“Through Innospexion’s advanced source and detection technology, coupled with decades of experience, we can generate a very high-quality image and then accurately interpret that image to see these fine bones very well,” he explains. “This improves detection and false rejection rates thus reducing waste and improving sustainability.”

The unprecedented accuracy of Innospexion’s fish bone detection system allows customers to deliver a better final product, and in the process benefit from optimal pricing and the ability to enter new markets.

With reduced reworking and more accurate bone detection, the system not only increases yield, it also enables customers to make labor savings and frees up workers for other tasks along the line.

“The benefits of this experience for JBT customers is a well-built and simple machine that detects small lightly calcified bones in fish and poultry better than any machine in North American plants today,” Carbone adds.

FIND OUT more about JBT Innospexion fish bone detection X-ray technology!