JBT Marel’s capability to offer comprehensive processing solutions for businesses of all sizes is a cornerstone of our success, further highlighted by the synergy between JBT and Marel. As a full-solution provider, we offer entire processing lines from a single source, ensuring seamless integration and efficiency. This extensive line-up will be prominently featured at IFFA, the premier food industry exhibition, held in Frankfurt, Germany, from May 3-8, 2025.

At this year’s IFFA, we’ll be showcasing a comprehensive range of cutting-edge equipment designed to revolutionize your processing line. From preparation to packaging, our lineup is set to impress. Let’s dive into the details of what you can expect to see at our booth from the forming to freezing range.

Precision Forming with the Marel RevoPortioner

Picture this: crafting perfectly uniform burgers, nuggets, or fish cakes with remarkable ease. That’s the promise of the Marel RevoPortioner, a must-have for any food processing operation. This advanced machine operates at low pressure, preserving the natural texture and structure of your raw materials while ensuring consistent shape and weight across every product with minimal waste. Whether you’re working with whole muscle or emulsion mass, the RevoPortioner’s interchangeable forming drums offer the flexibility to create virtually any 2D or 3D shape you envision. The RevoPortioner guarantees a high-quality finish and a clean working environment, benefiting downstream processes like flouring, battering, and breading.

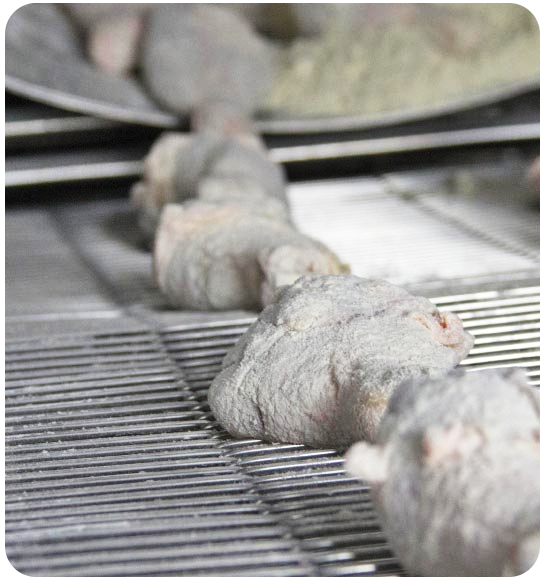

Achieve Consistent Homestyle Coating with JBT alco’s Specialized Equipment

The JBT alco Coating Line is a versatile solution for coating a wide range of products, from schnitzels and chicken nuggets to plant-based meat alternatives. At our IFFA booth, you’ll find a perfectly configured Coating Line setup, featuring a Preduster, Battering machine, Drum Breader, and an Urtasun Shaker—ideal for creating popular homestyle coated products. The alco Coating Line, with its versatile production widths ranging from 250 mm to 1,000 mm, is designed not only to streamline your operations but also to be tailored to fit the needs of both small companies and large industrial groups, adapting seamlessly to your evolving requirements.

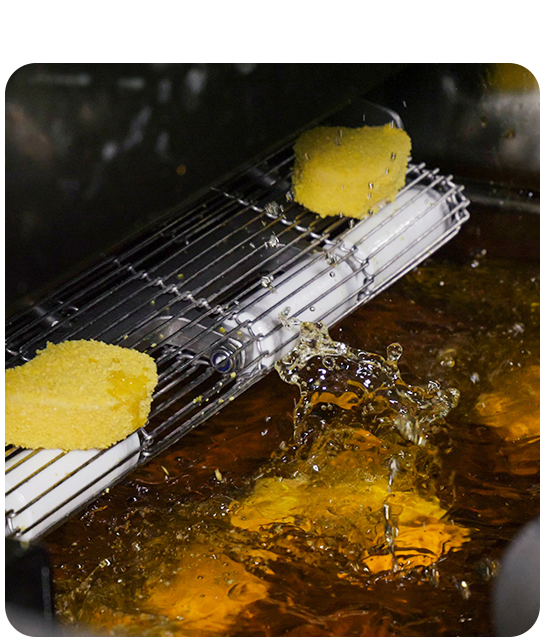

JBT alco Fryer: Efficiency and Safety

Imagine a fryer that not only delivers perfect results but also adapts seamlessly to your production needs. The JBT alco Fryer is designed to do just that, offering multi-purpose, continuous operation to fry a wide range of products in fat or oil. With options for electrical or thermal oil heating, this fryer provides energy efficiency and flexibility, making it a valuable asset in any processing plant. Its efficient heating system ensures low energy consumption while keeping oil temperature constant. And here’s the real kicker: the integrated sediment removal system and oil circulation system optimize energy transfer and temperature distribution, enhancing both safety and product quality.

Low footprint, high yields with the JBT alco Spiral Oven

Space constraints are a familiar issue. Here’s an oven that works effectively without taking up too much room. The JBT alco ASH Spiral Oven is designed to do just that, cooking and browning products with steam, hot circulating air, or a combination of both. Its spiral system maximizes process length while requiring minimal space, providing a practical solution to the common challenge of limited floor space in production facilities. With its guided, horizontal airflow, it ensures even heat distribution, producing juicy, consistently cooked products with ideal color and texture at high yield—effectively solving the issue of inconsistent product quality. In today’s diverse market, adaptability is crucial, and the spiral oven delivers with configurable cooking conditions tailored to nearly any product type.

Compact Efficiency with Frigoscandia GYRoCOMPACT Freezer

At IFFA, the Frigoscandia GYRoCOMPACT® 40 self-stacking spiral freezer stands ready to deliver efficient and reliable freezing quality. Compact yet powerful, the GC40 is capable of freezing up to 1,000 kg/hour, making it an ideal choice for start-ups or companies transitioning from cryogenic methods. In today’s world, where energy costs are rising, the GC40 offers a more economical and sustainable alternative to liquid nitrogen-based freezing. Despite its small footprint, this freezer doesn’t compromise on features—it includes the FRIGoBELT® Nova self-stacking belt to maintain product integrity and the FRIGoDRIVE® system to ensure smooth operation without jamming. Hygiene is a priority, with an open profile design that minimizes dirt traps and simplifies cleaning.

Join Us at IFFA 2025

At JBT Marel, we are committed to providing innovative solutions that enhance efficiency, quality, and flexibility in food processing. We invite you to join us at IFFA 2025, Hall 8.0, Stand H44 to experience firsthand the capabilities of our equipment lineup, including the Marel RevoPortioner, JBT alco Coating Line, JBT alco Fryer, JBT alco Spiral Oven, and Frigoscandia Freezer. Don’t miss the opportunity to discover how our technology can transform your processing line and help you stay ahead in the competitive food processing industry. Visit our IFFA webpage to learn more about our showcasing scope: jbtc.com/foodtech/visit-us-at-iffa.