Reduce labor and improve yield with innovative automated solutions from the DSI™ team at JBT. These systems – on display at IPPE 2022 – trim, slice and optimally portion poultry, beef, pork, plant-based protein, fish and even bakery products; in the process cutting out obstacles to having a profitable protein business.

DSI Portioning Systems employ machine vision technologies to scan food products and determine product shape, weight, and fat; preplanning and optimizing each piece for maximum value before the first servo-driven automated cuts take place. DSI systems cut with high pressure waterjets, horizontal blades, and vertical blades to maximize yield processor profit.

More Solutions More Efficiently

JBT will display and demonstrate the DSI 800 S series Waterjet Portioning System at the International Production & Processing Expo (IPPE) in Atlanta GA from January 25-27, 2022. The DSI display will highlight the latest advances in high-yield waterjet portioning as well as an efficient and rugged new intensifier pump technology proprietary to JBT that uses 40% less power to deliver 4000 or 6000 bar water pressure.

High-Yield Adaptive 3D Portioning (A3D)

The DSI 800 Series Portioning System is complemented by the DSI Adaptive Slicer 3D™ to achieve high-yield portioning of large-bird input product. The system combines waterjet cutting with intelligent horizontal slicing to achieve three-dimensional portioning. The new Adaptive slicer features wider lanes and improved systems to adapt to shape and size variation of incoming product to maximize yield.

“With the A3D system we have the ability to portion double weight product to template on the waterjet and then we intelligently horizontally slice the product to generate a top and bottom portion,” explains Dave Faires, DSI Director of Applications and Portioning Segment Leader. “For some applications we achieve six or eight shape-and-weight controlled portions from the original input product.”

Labor Saving Solutions

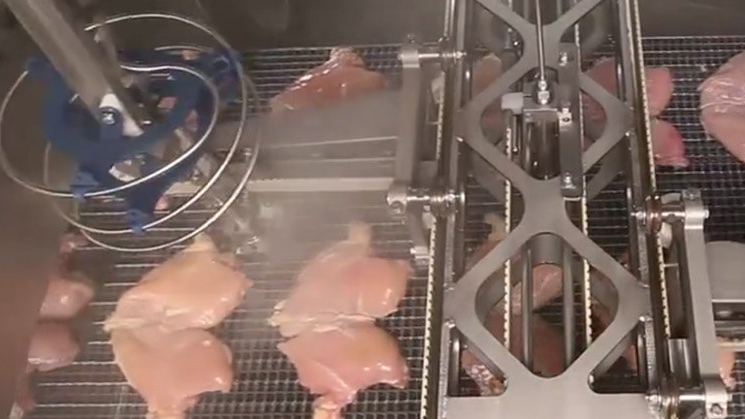

The DSI portfolio includes labor reducing solutions for poultry processors serving quick service restaurants or retail products. The popular DSI Dual Robot Harvesting System (DRH) (pictured above) reduces the labor required to separate portions from value added elements of the portioning process such as nuggets, chunks or strips bound for downstream bulk processing such as marination.

The latest innovation in the portfolio is a proven and exclusive solution for net weight packing and tray packing and high speed sorting or “calibrating” of fillets. JBT is introducing the proven Robotgrader system, updated and tuned for the needs of the North American market under an exclusive distribution agreement. This automated system scans product to determine shape and orientation, weighs the product in motion, and then robotically picks and places product according to maximum value at the highest production rate available in the least space required for such a solution.

“All four DSI solutions will be on display at the expo, alongside a video kiosk demonstrating our applications and our JBT remote support and IoT solution, called iOPS,” Faires adds.

JBT will be exhibiting at IPPE 2022 in Atlanta GA from January 25-27 in Booths C12743 and C12943 at the Georgia World Congress Center.

CLICK HERE to request more information or a meeting at the booth