Protein processors across Europe – and indeed worldwide – have been facing enormous inflationary pressures over the last 12 months, with rising raw material and input costs presenting a major challenge to food companies; one hardly alleviated by consumer expectation of low prices. Faced with such challenges, many processors are being forced to either raise prices or cut costs, but JBT DSI offers a third option that could deliver a solution for many in the industry.

DSI™ Waterjet Portioning Systems provide a proven means of achieving substantial labor savings while at the same time increasing productivity and improving yield, and all with the help of water.

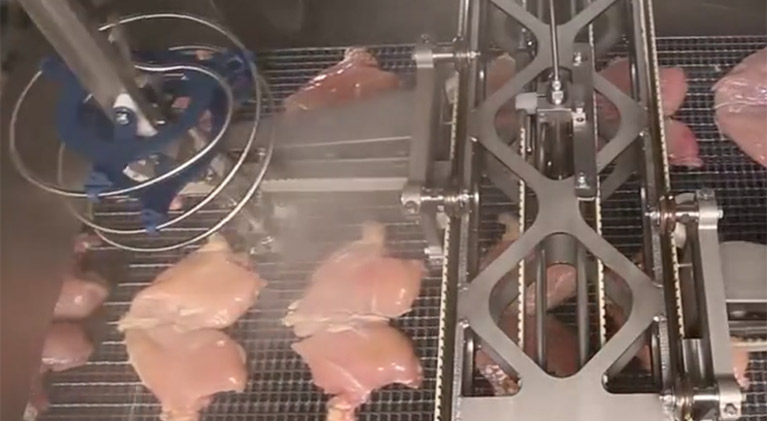

A worldwide success story, DSI Waterjet Portioning Systems are ideal for fast, effective, automated portioning of poultry, meat or seafood, resulting in a superior yield. The system is equally effective in producing portions, nuggets or chunks, fat-free product or strips, and can quickly change applications at the push of a button.

Optimizing profits

How does it work? As each piece of poultry or meat enters the DSI system, it is individually scanned to locate fat and determine shape, thickness, weight, and other attributes. Proprietary DSI Q-LINK™ Portioning Software will then optimize a cut strategy for individual piece of raw product, before computer positioned high-pressure waterjets generate complex cut shapes that make each piece as valuable as possible to maximize profits.

Incredible flexibility

“The huge advantage with DSI is that customers can save having to employ up to 50 persons on a line by installing a Waterjet Portioning System,” explains Niels Buengeler, Area Sales Manager for JBT DSI in Europe. “This is particularly important when many companies across Europe are looking to make labor-savings and more yield by investing in automation.

“The DSI Waterjet System will scan a product as it goes in, calculate the cut pattern, adapt it based on the scan and cut based on that calculation. This is a real superior technology compared to a lot of what has been previously available on the market.”

Also worth mentioning, he continues, is the incredible flexibility offered by the DSI Waterjet System. Using built-in portioning software, the equipment can produce retail cuts and trim fat at proven belt speeds of up to 30 meters per minute. Typically achieving two percentage point yield increases, the technology is now included in more than 500 installed JBT units.

For those customers keen to try the technology out for themselves, Buengeler adds that tailored tests using DSI™ Waterjet Systems are available at the JBT Food Technology Center for Protein in Helsingborg, Sweden.