Water is an essential resource in the poultry processing industry. From cleaning and evisceration to chilling and de-boning, water plays a vital role in ensuring food safety and maintaining high-quality products. However, with increasing environmental concerns and water scarcity, the industry must find innovative ways to reduce water consumption. One such solution is the Prime Water Reuse System, an innovative technology that helps poultry processors save millions of gallons of water each year. As Martin Knowles, Senior Sales Engineer, explains, “The Prime Water Reuse System is a game-changer for sustainable water management. It is an easy-to-use, cost-effective, and environmentally friendly solution that can help businesses achieve their sustainability goals.”

The Future of Sustainable Water Management: JBT’s Prime Water Reuse System

JBT’s Prime Water Reuse System is a game-changing solution that allows businesses to save water, reduce costs, and achieve their sustainability goals with minimal initial investments. The system is designed to be easy to install, use, and maintain, making it a practical choice for various applications.

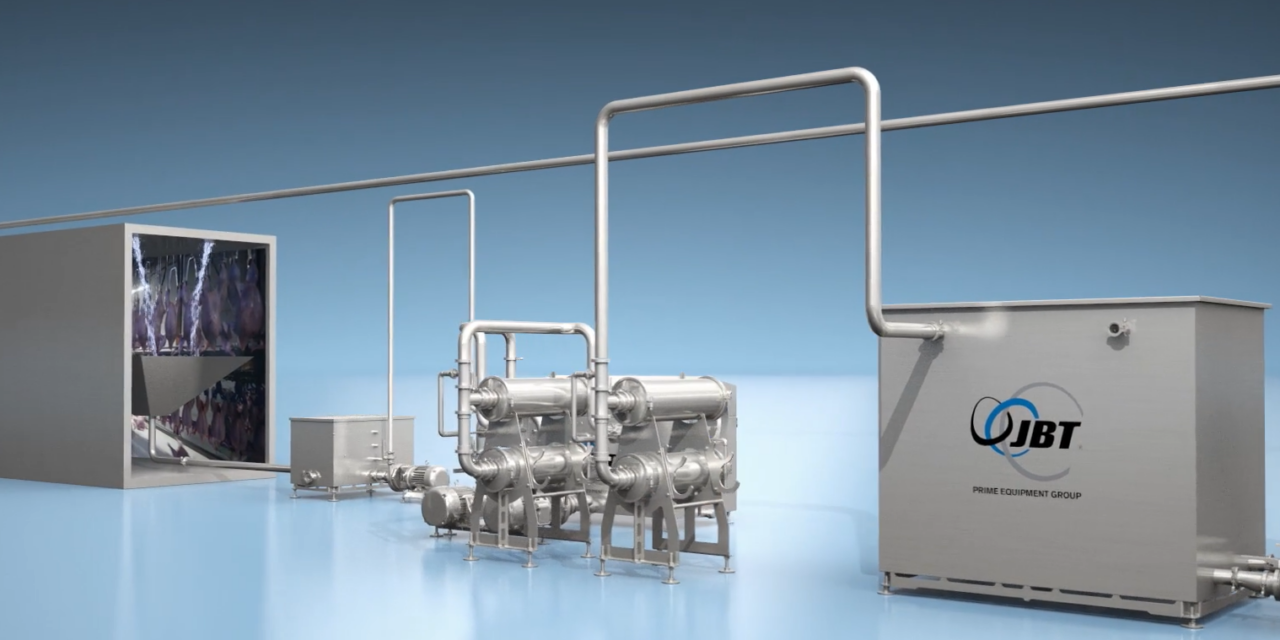

The Prime Water Reuse System was developed with USDA (US Department of Agriculture), with the main goal of reducing water consumption in the poultry processing industry. The system works by collecting water used during the evisceration process, screening it to remove solids, and treating it with chemicals to reduce the microbial count. Once treated, the water is then reused upstream in the process, where it was initially collected.

The system is designed to be efficient, cost-effective, and environmentally friendly. It can save up to 1.5 million gallons of water per week, depending on the size of the facility and the amount of water used. This reduction in water usage not only benefits the environment but also translates into significant cost savings for poultry processors.

How the JBT Prime Water Reuse System Works

The Prime Water Reuse System is custom engineered by JBT’s team of experts to screen, filter, treat, and reuse water in your facility, minimizing costs while maintaining safety and sanitation. The process is kept as simple as possible:

- Collect water from water-intensive processes.

- Remove solids with screens.

- Remove smaller particles with filters.

- Add microbials to break down remaining organic matter efficiently.

- Sanitized water is pumped upstream for reuse in places that previously required fresh water.

By reusing up to 90% or more of the collected water, companies can reduce their overall water usage by as much as 20%, depending on the application. As Nicholas Gasbarro, Product Manager at JBT Prime, explains, “The system is designed to be efficient, cost-effective, and environmentally friendly. It can save up to 1.5 million gallons of water per week, depending on the size of the facility and the amount of water used. This reduction in water usage not only benefits the environment but also translates into significant cost savings for poultry processors.”

Applications and Customization

The JBT Prime Water Reuse System is suitable for a wide range of applications that require intensive water use, such as poultry evisceration lines, chiller and scalder lines, pre-treating water before sending to municipal systems, and washing fruits and vegetables.

JBT Prime engineers can also customize controls packages that balance your facility’s incoming water volume and water needs with a self-balancing system that requires minimal manual oversight. This flexibility allows businesses to achieve significant water savings, with some customers saving over 1 million gallons of water per week.

Features & Benefits

One of the key innovations of the Prime Water Reuse System is its automation and auto-balancing features, which ensures a consistent flow of water throughout the process and reduces the need for manual intervention. Gasbarro explains, “The Prime Water Reuse System is designed to screen, filter, treat, and reuse water in your facility, minimizing costs while maintaining safety and sanitation. The process is kept as simple as possible to give your business an automated and sustainable solution that can easily integrate into your existing line.”

The JBT Prime Water Reuse System offers a host of features and benefits:

- Easy to operate: Automated and intuitive design with minimal maintenance.

- Integratable: Seamlessly integrates into existing processes.

- Sustainable: Conserve water and contribute to a more environmentally responsible future.

- Compliant: Developed and tested in compliance with USDA regulations, potentially eliminating municipal fines for excess water usage.

- Efficient and cost-effective: Reuse 90% or more of collected water, reducing overall consumption and associated energy costs by up to 20%.

- Superior performance: Remove solid particles greater than 0.008 inches (200 microns) in size, with capacities ranging from 50-70 GPM.

Your Reliable Partner for Sustainable Water Management

With over 20 years of experience, JBT Prime’s engineering team excels in designing simple, effective solutions tailored to diverse customer needs. JBT is committed to its sustainability efforts by providing innovative technologies like the Prime Water Reuse System to customers. We understand the importance of corporate social responsibility and strive to create a positive impact on the environment and society.

JBT continues to promote sustainable practices among our customers, partnering with them to find solutions that reduce their environmental impact while increasing efficiency and profitability. As Knowles emphasizes, “With JBT as your reliable partner for sustainable food production, you can be confident that you are investing in an innovative, cost-effective, and environmentally friendly solution.”

Our team of experts works closely with customers to identify opportunities for sustainability improvements, recommending solutions that align with their unique needs and goals. This commitment to innovation has enabled us to develop technologies like the Prime Water Reuse System, which is changing the way the poultry processing industry manages water consumption.

The JBT Prime Water Reuse System is an innovative, sustainable, and cost-effective solution for businesses looking to reduce water and energy consumption. With easy installation, minimal maintenance, and customizable options, this system is an essential investment for companies aiming to achieve their sustainability goals. With JBT, you can be confident that you have a reliable partner right down the line.