By Carlos Fernandez, EVP Customer Sustainability & Market Development

Food processors across the meat, poultry, fish, and plant-based protein sectors share common challenges, such as maximizing efficiency and meeting growing sustainability demands. It is perhaps unsurprising therefore that many food processors are looking to get the most out of their existing equipment and extend their working life.

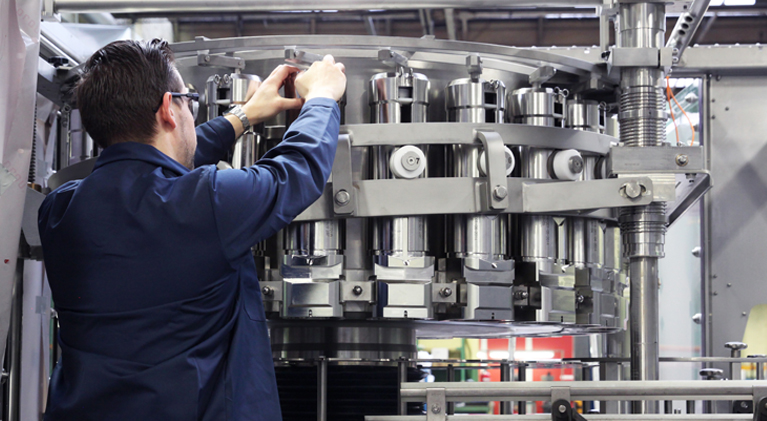

At the same time, however, many are acutely aware of the need to keep equipment up-to-date and in optimum conditions. JBT addresses these challenges by helping customers enhance the performance of their existing equipment and extend its working life through the Green Retrofit program and Research & Technology Centers (RTCs).

Green Retrofits

The key to sustainability for our customers lies in the efficiency and the productivity of their equipment, and this is exactly why JBT provides a Green Retrofit program.

This program enables customers to upgrade older equipment to match the performance level of newer systems without the need to change all of their install base, promoting a circular economy. Through our Green Retrofit program, we help maximize the performance of installed equipment by improving its productivity and efficiency, while at the same time minimizing its impact on the environment.

A prime example of this is the JBT Air Defrosting (ADF) upgrade kit, which allows customers to run freezers for more than twice as long between defrosts. By eliminating frost and snow build-up within the freezer, customers are able to increase freezing efficiency and product output, as well as substantially extend the time between defrosts and cleaning.

Another important green add-on provided by JBT are Fan Upgrades, which lower or stabilize energy consumption while helping boost production using frequency convertors. Through these solutions, we help protein processors not only increase production, but also save energy and water, while maintaining good equipment performance levels.

Upgrading Cleaning Software can also be hugely helpful in saving water and energy consumption. JBT’s cleaning solution kits and upgrades enable customers to save on labor – the single highest cost associated with cleaning – by automating the entire process, which ensures consistency and full traceability. The upgrades further optimize cleaning procedures and water consumption for hot and cold water, allowing customers to save on the second-highest cost – water – plus achieve major energy savings.

Even more than this, customers will able to streamline the process through the process through the creation of new cleaning formulations, while JBT’s interconnected OmniBlu service provides digital tools and insights for monitoring and optimizing cleaning utilities.

Research & Technology Centers

JBT Research & Technology Centers (RTCs) serve as a Research & Development resource for customers that focuses on maximizing the effectiveness and productivity of new or existing equipment and extending its working life.

RTCs contain – often full size – replicas of JBT equipment capable of reproducing the exact same processes that food processors use when portioning, preparing, forming, coating, frying, cooking, or freezing. Customers are able to draw on JBT experts’ substantial food safety, food science, and application knowledge to get the best results from their equipment and the desired end results for their products.

Many companies know how to weld steel or bend metal, and JBT is no exception, but we also understand the products and the processes. This means customers can be confident we can help them deliver products with the best-possible yield, shelf-life and food safety, and all with the aim of achieving optimum end results.

By replicating the performance of an industrial-level processing facility, we can assess the optimum conditions necessary for achieving sought-after results with food products. JBT further utilizes the expertise of its technicians to provide customer training to maximize the handling of existing products and processes, as well as covering the testing of new equipment.

RTCs also host live demonstrations, enabling customers to view, in-person, the workings of processes they might have previously only seen in presentations.

Sustainability in action

The key elements of sustainability provided by JBT can be simply summed up as process knowledge and application knowledge.

Process knowledge is vital because it can help ensure products reach consumers in optimum conditions, avoiding pitfalls such as overcooking, which is not only a waste of energy but also causes damage to the product. JBT technicians’ in-depth process knowledge will help your facility to meet food safety requirements and increase product shelf-life. This means not only fewer products going to waste, but also that your business will become more sustainable as a result.

Through the FTCs, we provide customers with data and information on how to operate more efficiently. In fact, many customers have told me that the foundation of sustainability lies in the reliability and the performance of the equipment.

How do you achieve this? Through a high standard of technology, maintenance and – most of all – knowledge of how to best operate the equipment. Not knowing how best to do this can result in a waste of human resources, equipment and the costs incurred when operating a line.

In terms of application knowledge, we provide support to customers to assess the functioning of equipment in their own facilities. We make sure they don’t have a food safety problem or are unnecessarily wasting high quantities of energy or water.

But JBT’s sustainable advantage for protein processors doesn’t end there. JBT DSI’s Waterjet Portioning System optimizes cuts of poultry, meat and pork to millimeter precision in order to maximize yield and minimize unnecessary wastage. All these processes can be tested by customers in our FTCs and then replicated in their own facilities.

Transforming the Industry with Sustainable Solutions and Cost Efficiency

So, is sustainability and making cost savings viable and compatible? Absolutely. Helping customers become more sustainable by getting the most out of their products is the essence of JBT.

JBT’s Green Retrofit program and Food Technology Centers effectively demonstrate the harmony of sustainability and cost savings. By helping customers enhance the performance of their equipment and adopt sustainable practices, JBT is committed to promoting a more sustainable future for the food processing industry.