As the global stage for cutting-edge food technology, IFFA 2025 presents an unparalleled opportunity for protein processors to explore solutions that address their most pressing challenges. Join our JBT Marel booth at IFFA to discover how these solutions can meet your operational needs and elevate your production capabilities.

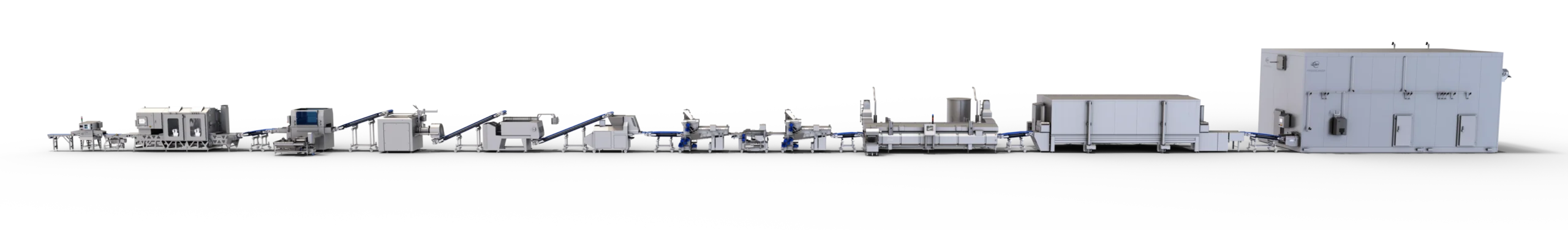

In the industry of meat and poultry processing, where precision, efficiency, and quality are fundamental, technologies like the Marel V-Cut Portion Cutter, alco’s Flattener, the DSI™ 812 Compact Portioning System, and Schröder’s IMAX Injection Technology stand out as key advancements. These systems are engineered to optimize operational workflows and improve the quality of processed products. Each technology brings unique capabilities to the table, addressing specific processing needs and helping processors maintain competitiveness in the market.

Precision Portion Cutting with Marel V-Cut

The Marel V-Cut Portion Cutter is set to make its mark at IFFA this year, showcasing its innovative approach to meat and chicken processing. The solution provides to the processors uniformly thick slices of the same weight, based on the shaping process and a servo drive technology combined with the advanced spiral blade. The flexibility of the V-Cut portion cutters can be tailored precisely to customer requirements in terms of mold selection, mold shape, and portion group placement.

The choice of portioning in best yield, weight accuracy, subdivision, and splitting gives customers great flexibility to fulfill current and future market requirements. Due to the high level of customization the Portioner can be integrated into line solutions. JBT Marel has developed a concept that offers customers a high-value chain and a high standard of hygiene, for example, in the production of schnitzel and steaks.

Enhancing Cooking Efficiency with alco’s Flattener

Achieving uniform product thickness is crucial for efficient cooking and maintaining product succulence. alco’s Flattener, which will be displayed at this year’s IFFA, effectively addresses this need by standardizing product thickness. This standardization not only shortens cooking times but also enhances product quality by minimizing the memory effect. With its adjustable roller system, the Flattener allows processors to precisely define the desired thickness, ensuring consistent results across a variety of products like schnitzel and gyros. This capability not only boosts cooking efficiency but also seamlessly integrates with other portioning systems, such as the Marel V-Cut 180 and DSI™ 812 portioner, offering a comprehensive and cohesive approach to meat processing.

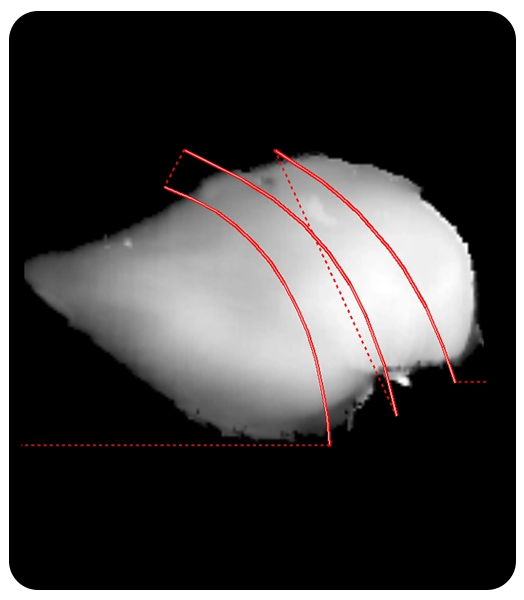

Space-Saving Precision with DSI™ 812 Compact Portioning System

Limited floor space often challenges processors in implementing advanced cutting technologies, but the DSI™ 812 Compact Portioning System elegantly overcomes this hurdle. With its small footprint and high-precision waterjet cutting capabilities, it seamlessly integrates into tight spaces without compromising performance. The system’s onboard scanning and Q-LINK™ software work in tandem to customize cut strategies for each piece of raw product, ensuring maximum yield and minimal waste. By automating the portioning process, the 812 not only enhances accuracy and throughput but also minimizes human error. DSI portioners consistently deliver automated, uniform shapes, potentially boosting yield by up to 25%, and will be showcased at IFFA for those interested in seeing its capabilities firsthand.

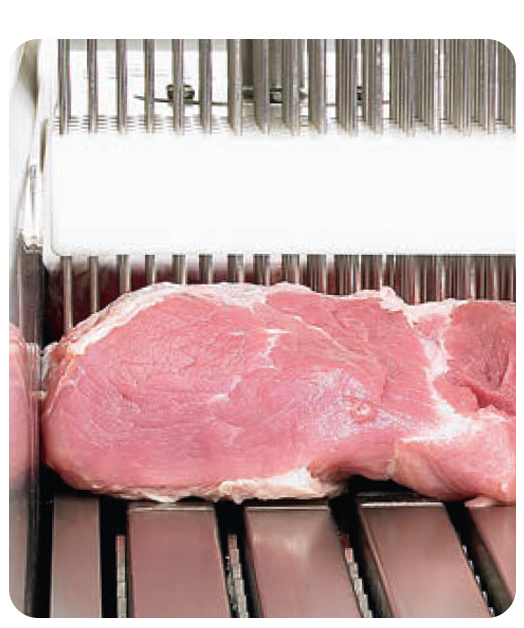

Optimized Injection with Schröder IMAX Technology

Injection curing plays a vital role in enhancing the flavor and texture of protein products, and Schröder’s IMAX Technology offers a sophisticated solution to this process. Featuring a hollow needle system and customizable stitch patterns, this technology ensures precise brine distribution, making it suitable for both boneless and bone-in products. With adjustable product advance settings, processors can fine-tune the injection process, whether their goal is achieving high injection rates or ensuring perfect brine distribution. This flexibility meets the diverse needs of protein processors, guaranteeing consistent quality and efficiency. Visitors to IFFA will find this technology on display, highlighting its application in the field of protein processing.

A Comprehensive Approach to Future-Proofing Protein Processing

These advanced technologies go beyond standalone solutions; they complement each other to form a cohesive strategy for tackling the complex challenges faced by protein processors. The Marel V-Cut Portion Cutter ensures precise portion cutting, paving the way for an optimal schnitzel value chain with alco’s Flattener. Meanwhile, the DSI™ 812 Compact Portioning System offers space-saving and unique portioning precision, and Schröder’s IMAX Injection Technology provides tailored brine distribution for improved flavor and texture. By integrating these innovations, food processors can streamline operations, enhance product quality, and stay competitive in the evolving food processing industry.

Visit our JBT Marel booth at IFFA 2025 in Hall 8.0, Stand H44, from May 3-8 in Frankfurt, Germany, to explore these solutions firsthand and discover how they can transform your processing operations, addressing your most pressing challenges and positioning your business for future success. Visit our IFFA webpage to learn more about our showcasing scope: jbtc.com/foodtech/visit-us-at-iffa.