Seeking protein injectors, massagers and tumblers with proven quality and reliability? JBT Schröder, a global leader in injection and curing technologies, is showcasing many of its innovative solutions at Anuga FoodTec, the food industry trade fair which runs until March 22.

Whether you are planning to attend the event or not, it’s worth learning more about the systems offered by Schröder that help processors deliver uniform, high quality poultry, meat, fish and plant-based protein products.

JBT Schröder’s IMAX 630 – from the HIGHLINE series – is a classic belt injector designed for small-sized products or industries where product transport primarily utilizes belts. The injectors are especially popular with customers in the pork, beef, fish, poultry, cheese, and plant-based industries.

Key features:

- High needle density and low injection pressure ensuring gentle and uniform injection for delicate products like fish and poultry.

- Accommodates wide range of product widths, ensuring high level of output even for small and light foods.

The IMAX ECOLINE 420 (below) offers outstanding Schröder quality at a favorable entry price and low operating costs in the basic version. Suitable for a wide range of products, the IMAX 420 features a proven, robust drive concept and thoughtful hygienic design.

Key features:

- Easy accessibility of all parts for cleaning and inspection. The manifold can be easily opened for quick and efficient cleaning.

- Available in two manifold variants (number and density of needles) and equipped with a needle suspension block, making it suitable for bone-in and bone-less products.

The FT 130/FT 200 filtration system supplies the IMAX ECOLINE and HIGHLINE injectors with up to 200 liters of brine. Plus an external rotary filter ensures effective filtration of the brine. The filtered brine is then returned to the injector through a stationary suction filter.

Quick and effective cleaning – disassembly possible without tools. To allow for easy cleaning, the rotary filter can be swung out, while the patented quick-lock system allows the suction filter to be removed within seconds.

Key features:

- Reduced operating costs thanks to low residue brine quantity.

- Fast and effective cleaning with a mounting able to accommodate all parts on the tank.

- Coarse particles are effectively filtered out using an external rotary filter with a scraper.

With the new BRIMAX 600 (above) all kind of brines can be produced for the injection process.

Schröder BRIMAX technology enables the standardized production of brine under the most stringent hygienic conditions. Using tried and tested BRIMAX components, the system’s 600-liter container offers great flexibility in the production of different types of brine.

Key features:

- The unique functionality of the software makes the system easy to use, ensuring consistent and repeatable results.

- Compliance with all hygiene requirements.

A compact massager with an integrated cooling and vacuum pump, the MAX 600 (below) is the ideal “plug and play” machine for batches up to 600 kg.

The operating principle of MAX technology is based on the horizontal mounting of a rotating paddle shaft in the fixed container, with the massage effect achieved by the spirally-arranged paddles.

The specific paddle positions generate a horizontal and vertical flow of material within the tank, resulting in a uniform and effective massaging action.

Key features:

- Up to 50% reduction in processing times compared to tumblers.

- Significantly higher levels of system utilization compared with tumbler technologies.

- Energy savings thanks to increased efficiency.

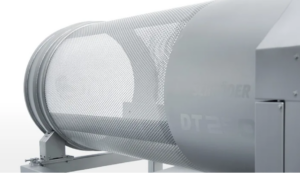

Last but by no means least, the DT 2500/3700 continuous tumbler is a 100% stainless steel massage and drainage drum for fresh meat used for massaging products and reducing surface brine. This brine is collected in a basin and can be transported back to the injector’s filter unit via a pump.

Key features:

- Drum length from 2500mm or 3700mm – excess brine can be effectively drained through the perforations.

- The basin collects surface brine, and the pump unit transports it back to the injector’s filter unit.

- The continuous tumbler can be equipped with fixed and swivel casters for easy maneuverability.

In addition to the exhibited machinery, JBT Schröder is digitally presenting new developments in IMAX technology, and will also be collaborating with visitors to demonstrate how solutions can be assembled to meet their production needs.

JBT will be exhibiting at Anuga FoodTec 2024 in Hall 6.1, Stand D090 F119 until March 22, 2024 in Cologne, Germany and you will be able to see all of these solutions first-hand.

Download the floorplan for a sneak-peak and book a demonstration today!