Is down time and long costly rebuilds hurting your productivity and bottom line? At the upcoming IPPE 2024 expo, which takes place in Atlanta, GA from January 30-February 1, a JBT team member will be demonstrating how a TT1815 high-speed, automatic double clipper can be taken apart and rebuild in a minimum amount of time to get production rolling again.

IPPE 2024 will also see Tipper Tie mark the official launch of both the TN2004 – an automatic ham packing system that nets big savings – and the RFDW2, a new, bone-in, whole-muscle netting machine.

Developed for the bone-in ham industry, the TN2004 features a complete redesign of Tipper Tie’s automated netting system, helping customers achieve significant savings on productive time, utility costs and maintenance. More than simply an update of the previous model, the TN2004 allows the netter to function with more automation thanks to the innovative auto change chute magazine which reduces operator dependance, increasing productivity and throughput.

Meanwhile, the RFDW2 is designed to support difficult-to-manage fixed diameter netting for whole-muscle hams. A step-up from the previous RFDW1, the RFDW2 supports the TN2004 by rucking the maximum amount of netting onto a chute, maximizing the run time of each full chute, minimizing the number of chute changes, and reducing wasted netting. This of course all increases productivity of the whole muscle netting operation.

Live rebuild demonstration

As well as getting a chance to learn about the newest additions to the Tipper Tie family, delegates to IPPE 2024 will be able to watch a live demonstration of a TT1815 rebuild. If you are struggling with down time, high rebuild costs, or long rebuild times, you do not want to miss this.

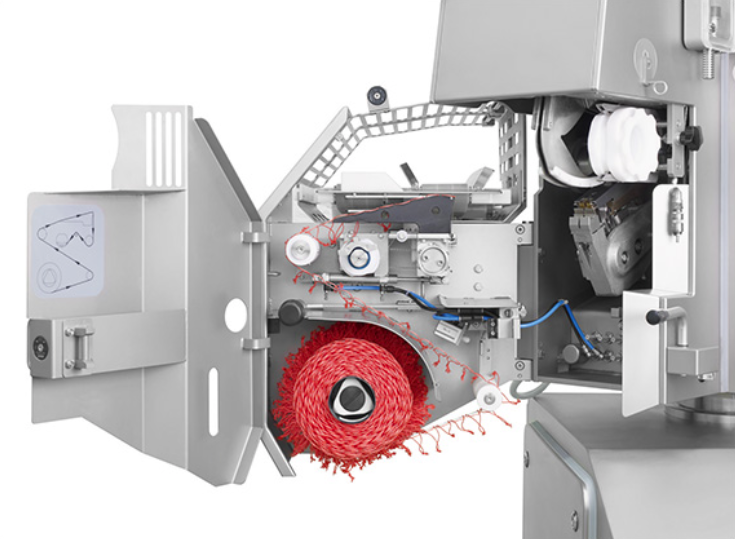

An industry-ready automatic double clipper, the TT1815 is the solution for high speed production of dry sausage like pepperoni, salami and a variety of chub products. However, every machine suffers wear and tear and requires proper maintenance to keep it running at its best, explains Tipper Tie’s director of project management, Conrad Faust.

“If you are struggling with down time, high rebuild costs, or long rebuild times, you don’t want to miss this.”

“The idea behind a rebuild is to replace worn parts before they become broken parts,” he says. “Broken parts oftentimes create more cost because if they break, it can cause other parts to fail and creates downtime because it never fails when it’s convenient. It fails when you’re in the middle of a production run and you’ve got meat in the cooler and the hopper and you’re trying to get product out the door.”

Rebuilds are a regular part of maintaining and keeping a production facility running at peak performance. Tipper Tie can rebuild a machine very quickly and this is what the team will be demonstrating at IPPE, Faust continues.

“We will be stripping down a machine and putting it back together in front of a live audience, right there on the showfloor,” he says.

“It’s the first time we’ve tried to do something like this, we’re pretty excited about it and we’d like anyone who is struggling with downtime or high rebuild costs on their chub lines to come and see how easy it is to take apart and put together Tipper Tie’s TT1815.”

JBT will be exhibiting at IPPE 2024 in Booth C22143 from January 30-February 1, 2024 in the Georgia World Congress Center, Atlanta, Georgia.