How can you effectively cook ungraded chicken pieces without overcooking, losing yield and affecting quality? JBT’s unique combination cooking system, which brings together the Formcook Contact Cooker with the Stein TwinDrum PRoYIELD™ Spiral Oven or alco Spiral Oven ASH, is leading the industry in helping processors deliver uniformly-cooked chicken pieces that maximize yield and boost efficiency across the production line.

As any processor will know, chicken fillets are by their very nature a product that can be difficult to standardize. When supplied to a processor, it’s common for fillets to come in a range of different sizes, shapes and forms.

But delivering consistent cooking results for such a product comes with its own challenges, explains JBT Manager for Coatings and Cooking Applications, Bart Kivits.

“When you set-up an oven, you have to make sure that the thickest product gets fully cooked, but the danger is that smaller products might get severely overcooked in order to achieve the uniform results on the same conveyor belt,” he says.

The result, he says, is yield loss. “Smaller products that are overcooked suffer more weight loss and that causes the efficiency of the line to go down.”

So how can JBT help? One such highly-productive solution is the JBT Formcook Contact Cooker. The system works in the form of a hot press: products are cooked on a teflon belt between two heated plates.

A hot-contact solution: the JBT Formcook Contact Cooker

The advantage here, Kivits explains, is that thick pieces of chicken can be pressed into a uniform thickness and simultaneously the top and bottom surfaces of the chicken are cooked. “Products that come out of the Contact Cooker have a uniform thickness,” he continues. “The big pieces are pressed flat and are partially pre-cooked before they move into the oven. It also means that the differences after cooking between smaller and thicker products are virtually nothing.”

“When the product enters the oven, it doesn’t need to be cooked for so long, resulting in an increase in oven capacity of between 2-4%”

A further advantage of contact cooking is its ability to improve yield by effectively trapping moisture inside the chicken pieces as they cook. Not only this, the process also improves flavor and quality by delivering appealing, succulent pieces of chicken rather than overcooked dry products.

“Typically, using a Contact Cooker delivers a 4% yield improvement,” says Kivits. “And then when the product enters the oven, it doesn’t need to be cooked for so long, resulting in an increase in oven capacity of between 2-4%. As a result, the whole system benefits from a higher yield and a higher capacity.”

End consumers also benefit with more consistent, uniform products.

Perfecting Cooking & Browning with Spiral Cooking

The most commonly used combination with the Contact Cooker is a spiral oven, such as JBT’s recently-launched Stein TwinDrum PRoYIELD Spiral Oven (pictured above).

Featuring patented double-impact airflow technology, the PRoYIELD takes the original TwinDrum two-zone cooking design and makes it even better by dramatically improving temperature consistency, allowing customers to improve product quality, boost yield and save energy.

The benefits of this leap forward in spiral oven design are substantial: an estimated increase in yield of up to 7% for chicken, and parallel energy savings of as much as 5%. To make this evolution in spiral oven design even more accessible to customers, the PRoYIELD can be easily retrofitted on existing TwinDrum ovens in little over a day.

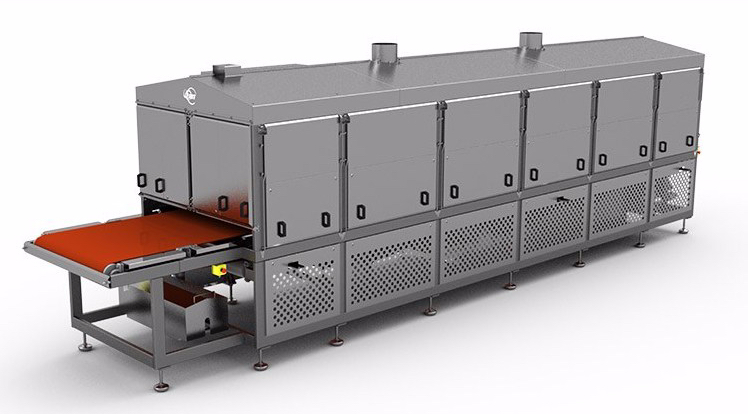

The alco Spiral Oven ASH (pictured), which is approximately half the size of the TwinDrum, offers a more economic option for customers with lower throughput, but with an equally high performance.

“The alco Spiral Oven ASH is probably the most compact Spiral Oven on the market which makes it perfect for production lines with restraints on space.

Contrary to what its compact size may imply, the smart design empowers it to efficiently cook impressive quantities, boasting capacities of up to 5100 kg of chicken nuggets per hour,” says Kivits. “It also amounts to a smaller investment to get the same benefits.”