As the global food processing industry gathers at IFFA 2025, innovation and efficiency remain at the forefront of discussions. Among the groundbreaking solutions presented, the JBT alco HotCook stands out.

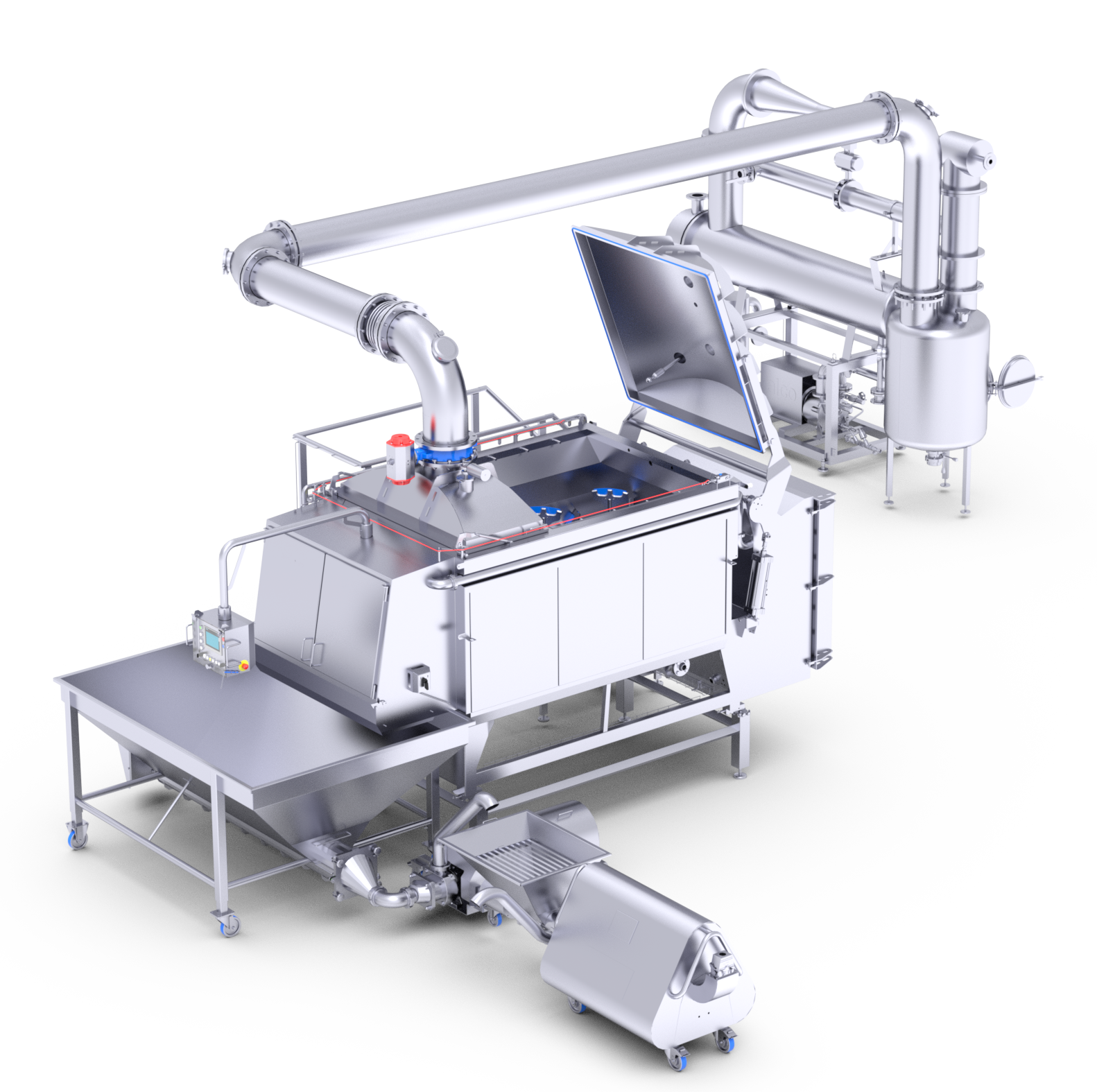

The cooking mixer presents itself as a multifunctional system for searing, cooking, boiling, and reducing products, achieving uniform temperature distribution through simultaneous mixing. From enhancing product quality to integrating versatility, the HotCook is designed to tackle the challenges of modern food production. This article explores how the HotCook’s advanced features offer practical solutions to common industry issues, ensuring a more efficient and sustainable future for food processing.

Homogeneous Cooking for Consistent Quality

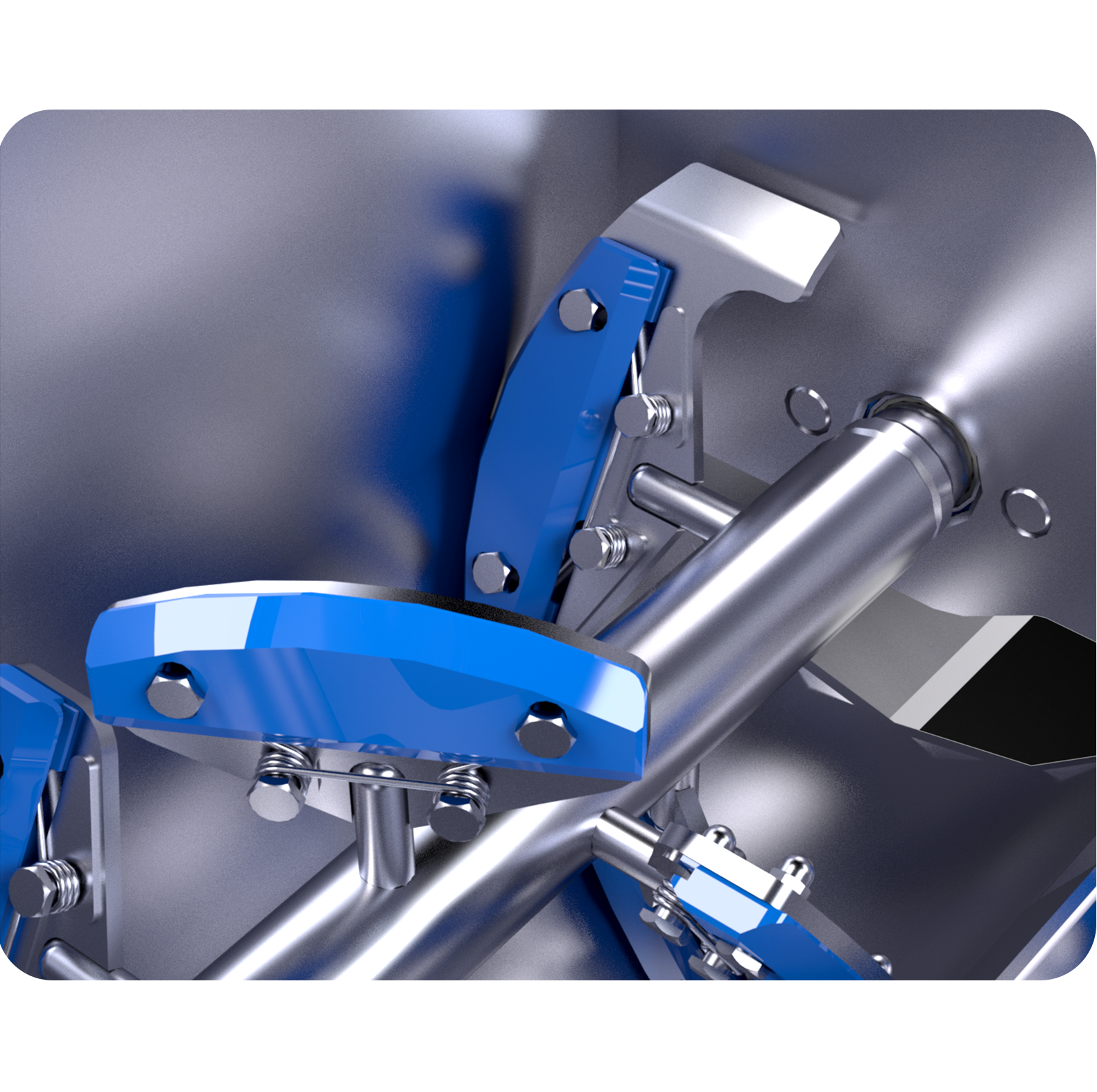

Could a simple design adjustment be the key to consistently achieving high product quality? The HotCook’s horizontal double shaft mixer paddles, equipped with special-designed mechanical scrapers, provide just that. By continuously moving the product against the heated area, the HotCook effectively prevents adhesion to the heated walls, a common issue that often results in uneven cooking and wasted product. This innovative approach is particularly beneficial for processors handling large batches, where uniformity in temperature distribution is crucial for maintaining consistent product quality.

Meeting Diverse Processing Needs

Food processors often face the challenge of adapting their equipment to handle a wide variety of products and processes. The HotCook offers an outstanding range of equipment options, allowing it to meet diverse processing requirements. “You can mix, cook, sear and chill in one machine,” says Volker Paland, Sales Director at JBT alco. “It can be used consistently for a huge range of products, from ready meals and stews to sauces and soups – the same machine can be used for an extensive range of applications.” Visitors to IFFA will be able to view the HotCook and see firsthand how it seamlessly integrates versatility and efficiency, providing a comprehensive solution for modern food processing challenges.

Rapid Heating for Optimal Flavor Preservation

In today’s competitive market, preserving the freshness and flavor of food products is fundamental. The HotCook’s rapid heating capability ensures that products reach high temperatures quickly, preserving their natural flavors and freshness. In fact, studies have shown that rapid cooking methods can retain up to 30% more nutrients compared to slower processes, making the HotCook an ideal choice for health-conscious brands. Additionally, with the increasing consumer focus on clean labels and minimally processed foods, the ability to maintain natural flavors without the need for artificial additives becomes a significant competitive advantage. This capability is especially important for processors aiming to deliver high-quality products that meet consumer demands for taste and nutrition.

Redefining Efficiency in Food Processing: The Promise of the HotCook

As the industry looks towards the future at IFFA 2025, the JBT Alco HotCook exemplifies the innovative solutions needed to address the evolving challenges faced by food processors. By focusing on consistent product quality, energy efficiency, and operational flexibility, the HotCook not only meets current industry demands but also sets a new standard for sustainable and efficient food processing. For processors seeking to enhance their operations, the HotCook represents a significant step forward in achieving these goals.

JBT Alco will be exhibiting at IFFA 2025 in Hall 8.0, Stand H44 from May 3-8, 2025 in Frankfurt, Germany. Visit our IFFA webpage to learn more about our showcasing scope: jbtc.com/foodtech/visit-us-at-iffa.