When it comes to freezing fruits, vegetables or even fish, pasta and rice, the problem of products sticking together into a homogenous mass can be all too common. But did you know that Individually Quick Frozen (IQF) technology from JBT’s Frigoscandia FLoFREEZE® can overcome these pitfalls and deliver improved product quality and yield?

Lars Michael Svensson, JBT Regional Sales Support Manager, here outlines some of the key advantages offered by the FLoFREEZE and provides tips on achieving consistently optimum performance.

One of the first advantages you have with the FLoFREEZE is its flexibility: you can quick-freeze a huge range of products with the same machine. For example, you can run small fish one day, pasta the next, rice the third and strawberries the fourth, and you can do all that with the same FLoFREEZE system.

At the same time and thanks to IQF innovations, the quality of the product coming out of the freezer is fantastic from all the customer feedback we have received. It is also a very efficient way of freezing products. By freezing fast, water loss is far lower, so you can achieve a very good yield. And thanks to its speed, the footprint of the FLoFREEZE is substantially smaller than a standard freezer system, which would need to be far larger to handle similar volumes.

Product quality is maintained thanks to gentle handling which allows delicate products such as berries, fresh spices and tropical fruits to be maintain their fresh appearance and flavor characteristics.

True fluidization

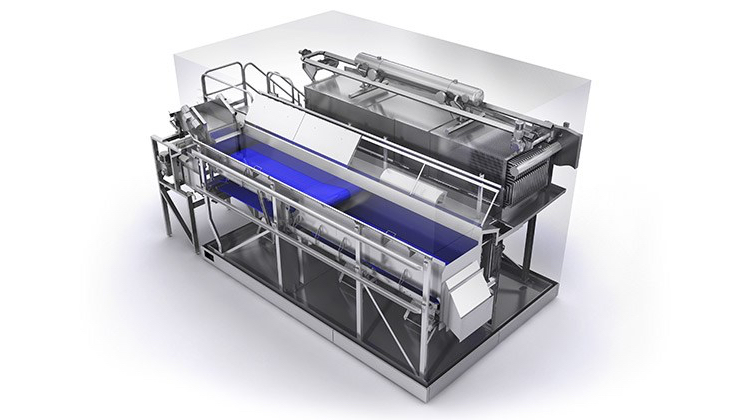

So how does the FLoFREEZE work? IQF technology uses an airstream to freeze products one-by-one. This allows for the movement of air around each product to separate them, so they don’t stick together. The FLoFREEZE provides true fluidization, using a patented air flow system that separates and freezes the most delicate products, while simultaneously fulfilling the industry’s toughest requirements for hygiene, economy and user-friendly operation.

Products typically run through the FLoFREEZE are smaller dimension foods that can fluidize, such as fruits, berries, vegetables, pasta and shrimps. The products float in the airstream, behaving like a liquid, which allows us to individually freeze the surfaces, so they won’t stick together.

Optimizing freezing

But how can customers get the most out of this technology? JBT offers a wealth of experience and knowhow that can be utilised to support customers in overcoming difficulties and finding the right solution for their specific products. With knowledge based on 60 years’ experience in IQF freezing and food processing, our food processing technologists will help guide and adapt processes according to customers’ production needs.

Effective solutions

Both inside and entering the machine, we have options to separate products depending on shape, dimensions and temperature. A vibratory shaker feeds the product into the machine, so you get an even-flow. Then inside the machine, on the first IQF track – where we carry out crust freezing – customers have the option of running an agitation process, meaning the product is moved back and forth rapidly to separate it.

The FLoFREEZE allows you to restrict the amount of air at entrance, to pre-cool the product before fluidization begins. Further, we have options to control air coming through the product bed: instead of a constant flow, we have a pulsator which opens and closes fast to variate the airstream causing the product to move up and down.

Once it moves onto the second belt, the product is taken down to -18C. Thanks to the process carried out in the first stage, the product can move to this second belt without having risk of sticking together and creating lumps. So using all these options, we help customers get the most out of their FLoFREEZE and enable them to benefit fully from the system’s flexibility, speed and undoubted effectiveness.