This article was originally published on JBT’s Plant-based Protein Blog.

Scientists have recognized plastic pollution as an environmental problem for a long time, but recently it has increased substantially and become more urgent to manage. Besides the visible plastic pollution, like bags and bottles, the focus also has come on the invisible form – the microplastic particles.

The study of microplastic contamination of food products and its impact on human food safety is an emerging field, but a lot is still unknown. Ingesting microplastics into the human body constitutes a probable hazard. For the food processing industry, the use of plastic parts that will wear down must be avoided in the food zone.

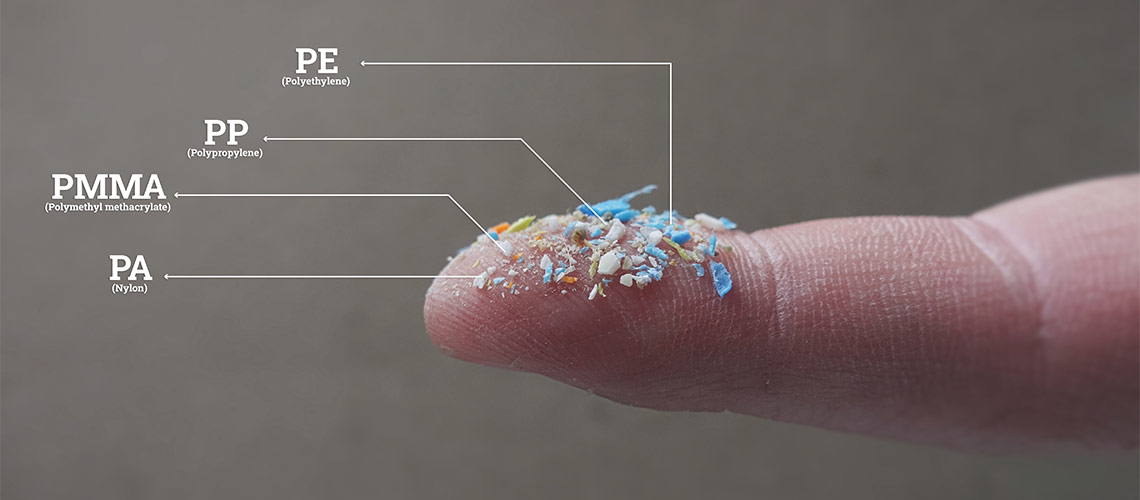

Microplastics are tiny pieces of plastic material that vary greatly despite their similarity of being very small in size. The smallest parts are not visible to the naked eye. Their composition can be any kind of plastic material, such as polyethylene (PE), polybutylene succinate (PBS), or polyvinyl chloride (PVC). They can also have different shapes, colors, sizes, and densities.

The small pieces of plastic can be grouped into primary and secondary microplastics based on where they come from before they end up in nature. Primary microplastics are already tiny when disposed of, coming from cosmetic products and various industries. Secondary microplastics come from larger pieces of plastic such as bags, bottles, and fishing nets that are disposed of and are subjected to weathering and then fragment into micro and nano plastics. Secondary microplastics account for most of those found in the oceans, ingested by marine animals.

Chemical contaminants

Microplastics may act as vehicles or carriers for environmental contaminants and other chemicals added during manufacturing. Chemicals such as styrene, toxic metals, phthalates, and bisphenol A, may be absorbed on the surface of microplastics and may act as “substrates.” These pollutants and additives can be transferred from ingested microplastics to animal tissues and cause impairment of crucial body functions.

Food and beverage operators need robust and accurate characterization tools and methodologies to understand the scale of microplastic contamination and reduce consumer exposure. Taking a proactive stance on microplastics is also a positive step from a brand reputation perspective.

Minimizing risk

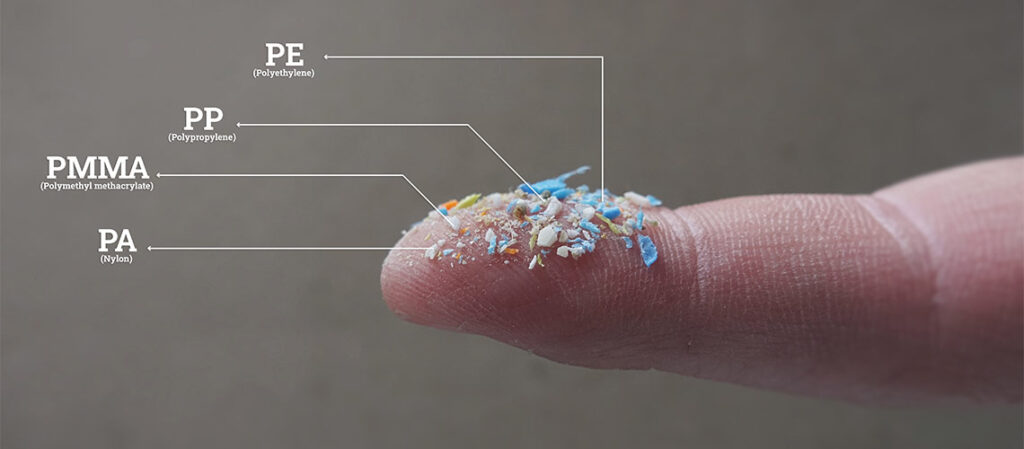

Microplastics can also originate from pieces in the food processing equipment. Using plastics in moving parts in sections that are in direct contact with the food increases the risk for contamination. As the parts are exposed to wear and tear, it can generate microplastics directly in food zone 1.

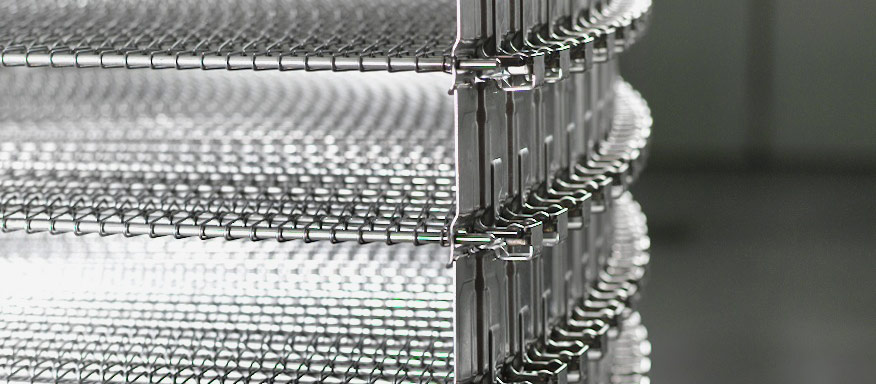

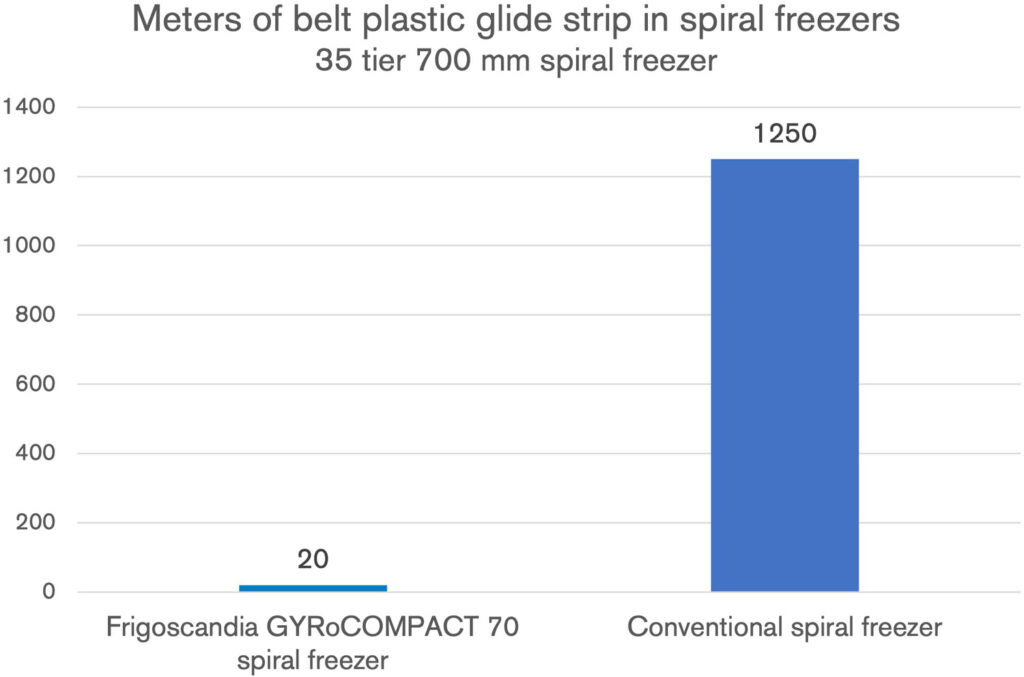

Conventional spiral freezers, for example, are based on plastic wear strips to achieve acceptable friction. When the belt moves alongside the drum on plastic-coated guides, the friction wears on the plastic and releases small microscopical parts. These wear strips has a typical acceptable wear of 1-2 mm over 20,000-30,000 hours of operation. A conventional 35 tier 700 mm wide belt spiral freezer has a total length of 1,250 m belt wear strips in tier carriers. The total area with 14 mm wear surface is 18 dm2. That gives a total volume of worn off plastic (1.5 mm wear) equivalent to 27 liters of microplastic, not counting wear strips in center drum.

Besides the apparent hazard, microplastic may also act as a vehicle or carrier for chemicals. That means that the processed ingredients also can get contaminated with oil from the machine and create black spots on the food. With this in mind, JBT designed the Frigoscandia GYRoCOMPACT® self-stacking freezer. Its unique Self-Stacking stainless steel mesh belt has no plastic parts in the food zone that can generate microplastics.

The GYRoCOMPACT has 25 meters of belt wear strips which is only 2% compared to the 1,250 m belt wear strips of the conventional spiral freezer. With the industry’s only self-contained 100% cleanable freezing zone, ease of accessibility throughout the enclosure, and easy evaporator access offering exceptional cleanability, it provides you with the ultimate performance in product hygiene.

At JBT, we know that the design of food processing equipment is essential for food safety. That’s why we always design to minimize all unnecessary surfaces and use as little material as possible to avoid dirt traps. We call it Hygiene by Design, and it is crucial in food zone 1, where the equipment has direct physical contact with the products. We also have specialists just focusing on reducing the use of unwanted materials like plastics.