Specializing in convenience protein products? One of the newest additions to the JBT family, alco, offers a portfolio of solutions that present the ideal fit for companies producing everything from chicken nuggets and stir-fry snacks to pasta and plant-based ready meals.

Worldwide, the convenience food market is expected to grow 4.2% annually over the next decade, driven by rapid urbanization, changing lifestyles and demand for on-the-go eating options, according to DataM Intelligence.

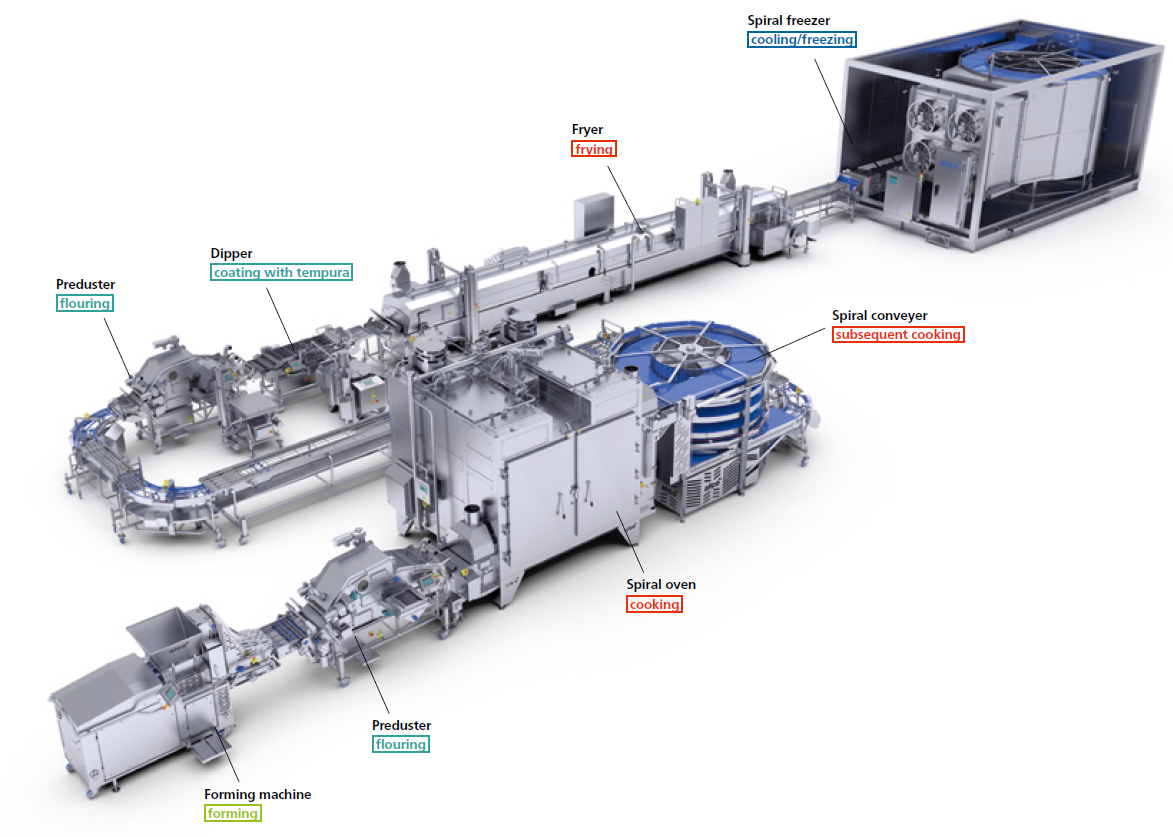

alco produces a wide array of processing equipment for the protein further processing market, covering forming, flattening, coating, frying, roasting, cooking, cooling and freezing. In addition to these high capacity convenience lines, alco also offers preparation solutions including mixing and grinding equipment.

The modular convenience lines from alco (below), which can be flexibly arranged according to each individual product, are the best solution for any need for high-volume, high-quality products with flexible, cost-saving product changeover.

Thanks to its broad machine portfolio and the ability to individually adapt to customer needs, alco brings the possibility to process many different products in many different ways. The alco machines complement Stein, Double D and FormCook processing equipment, expanding the range of solutions JBT can offer processors.

At the same time alco provides innovations and added value in the form of new technologies, equipment customization and process development in close cooperation with customers, explains Bart Kivits, JBT’s Manager of Coating and Cooking Applications.

“alco’s complementary solutions are ideal for customers producing products like chicken nuggets but also meat, fish and plant-based products, while the alco HotCook mixer-cooker is well-suited to preparing minced meat, pasta sauces and stir-fry products,” says Kivits. “The alco solutions also come with some sought-after features, such as stainless steel drives, excellent insulation, built-in hygienic design and system flexibility.”

From a JBT point of view, the addition of alco has been hugely valuable, bringing with it further oven options to the existing range, as well as expansion of the frying line. “The biggest advantage is we are now able to offer highly flexible processing equipment with smaller capacities and customized solutions for high capacity processing lines, and this is ideal not just for customers producing poultry products, but also for plant-based foods.” adds Kivits.