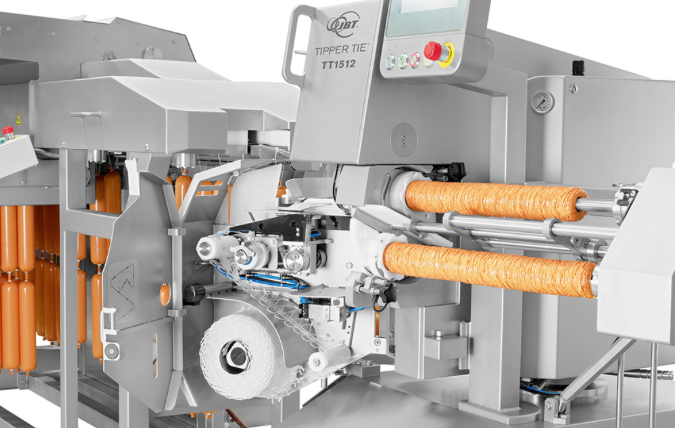

Struggling for capacity with your dried or smoked sausage operation? The new TTStick from JBT Tipper Tie offers an automatic hanging line with accuracy, speed and efficiency. Capable of handling 100 loops per minute – one of the fastest in the industry – the TTStick will also give you up to 25% more space utilization of your drying room or smoke houses.

The latest innovation in JBT Tipper Tie’s well-established automatic hanging line family of machines, the TTStick is designed for dried sausage, such as pepperoni and salami, as well as smoked or hung products, but comes with some significant improvements.

Compared with the previous model, explains Tipper Tie’s Conrad Faust, the TTStick has replaced much of the pneumatics with servo-technology and servo-motion, which is more economical, a lot more controllable and more precise.

“We’ve kept some of the design innovations from our SwiStickXXL and carried them over into our new TTStick,” says Faust.

“This is our third iteration of automatic hanging technology: we continue to improve and move our machines forward, and one of the things that sets our machine apart is simplicity, we use one chain to transport the loop and the sausage and put it on the stick. This delivers a simpler machine with fewer hand-offs, avoiding potential errors and problems, and future maintenance nightmares.”

“The TTStick is able to hang 100 loops per minute, which is one of the fastest – if not the fastest – in the industry right now,” Faust adds.

Productivity boost

According to Faust, the big advantage with an automatic hanging line, and particularly for dry sausage, is that it can consistently place product more accurately on a smoking-stick, resulting in better utilization of the smoking-stick and by extension drying rooms or smoke houses.

“Dry sausage like salami’s, chorizo, and capocollo, needs a lot of time in the drying room and we can give you up to 25% more utilization of your drying room, which has a significant impact on the potential productivity of a plant,” he says. “We can be more consistent than a typical human worker and get more product onto a smoke stick and therefore into a drying room, or smoke house.”

A further advantage is that the TTStick is compatible with most smoking sticks, meaning that instead of having to invest in new sticks, in most cases a facility can use their existing sticks.

And the TTStick can also have a positive impact on quality. The ever-important cultures which grow on the exterior of dried sausages are very important for their development, but these can be compromised by manual handling. “Given that the products don’t get touched by people once they are produced, customers don’t have to worry about cultures getting disturbed, leading to a better-quality end product,” Faust adds.