No business owner wants to receive a notification of a foodborne illness outbreak traced back to their facility. Unfortunately, these occurrences are all too common, with the US FDA reporting 48 million cases in the US alone every year. However, taking the right precautions can help you keep your food processing equipment in optimum condition and prevent contamination.

In fact, by applying a few simple steps and methods you can maintain your JBT equipment in an optimum and food-safe condition. For example, ensuring that cleaning employees are properly trained and using the right detergents and concentrations of cleaning chemicals can go a long way in keeping bacteria at bay.

Niklas Landby, JBT Business Support Manager

According to JBT Business Support Manager Niklas Landby, many companies suffer from bacterial issues due to inadequate cleaning. In order to avoid potential pitfalls and issues in your production facility, efficient cleaning, monitoring, and traceability are essential. Since JBT started, we have acquired a deep knowledge of food safety. All of our solutions are hygienic-by-design and easy to clean and maintain. As your committed partner, we are eager to help you improve the hygiene in your food production line.

Common causes

Landby identifies some common causes of bacteria issues in food processing equipment, such as using the wrong chemicals for cleaning, skipping cleaning steps or doing things in the wrong order, and not using enough water in the cleaning system. Other cleaning issues may be using the wrong detergents or in too-high doses, which can result in damage or corrosion to equipment.

“We know that the process of thoroughly cleaning the equipment takes time and can be both difficult and costly,” he says. “We can help the customers by offering training and solutions specifically designed for fast, thorough, safe and economical cleaning of the food processing equipment.”

How to prevent the spread of foodborne illness

So what are the principal steps that customers should take to keep equipment clean and food-safe? Landby recommends several key steps:

- Maintain cleaning equipment and make sure it’s functioning in the right way. Scheduling regular inspections and preventive maintenance are important factors for safe operations.

- Use JBT’s OmniBlu™ platform: Cleaning is often done by outsourced personnel and during hours with little or no other staff in the plant. To ensure that the cleaning is done consistently and orderly, you need to be able to track and document it. OmniBlu monitors and measures water volume and temperature, cleaning chemicals usage and concentrations and cleaning time. Moreover, OmniBlu provides you with the reassurance that cleaning procedures are being followed and potential bacterial growth issues prevented.

- Training: Use qualified personnel for cleaning, ensure contractors receive certified training before cleaning equipment, and provide on-site training for staff and contractors on using the cleaning systems. Procedures and behavior are a large part of making sure that cleaning is done correctly and minimizes the risk for contamination.

- Use the right detergents at the correct concentration when mixing cleaning chemicals. JBT has developed a series of detergents that meet the rigorous requirements of legislative and customers. Naturally, all of our products are designed to work within food production facilities. They can handle both extreme temperatures and prevent bacterial growth.

JBT’s Hygiene by Design Approach

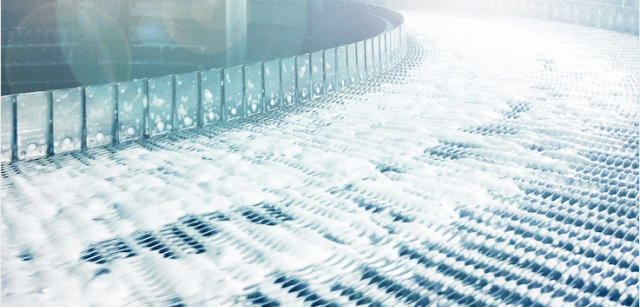

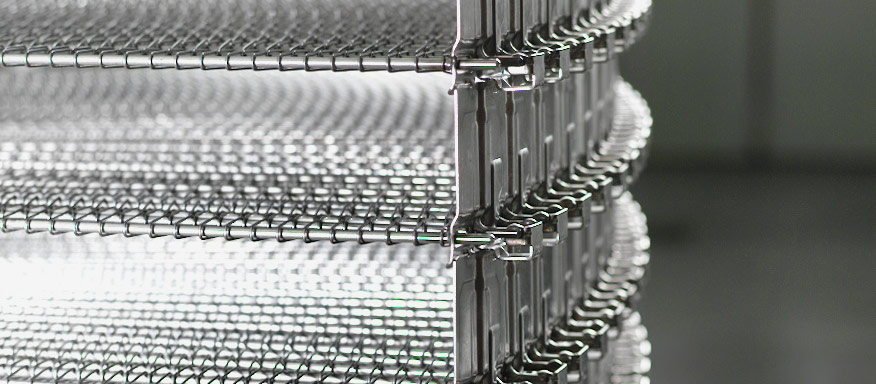

Food safety starts at the drawing board, where JBT designs equipment to minimize all unnecessary surfaces and use as little material as possible to avoid dirt traps. We call it “Hygiene by Design” and it is especially important in food zone 1, where the equipment has direct physical contact with the products, and surrounding food zones where biofilm can increase the risk for bacterial growth.

Preventing the spread of foodborne illnesses is crucial to the success of any food processing business.

JBT´s Frigoscandia GYRoCOMPACT®’s self-stacking belt design reduces the structural parts, which means fewer surfaces to be cleaned, less wasted water, and less detergent consumption. The Fully Welded Enclosures (FWE) is another innovation in hygienic design that combines disinfection with hot steam sanitation to remove the risk of biofilm and microbiological growth in a freezer unit.

In conclusion, preventing the spread of foodborne illnesses is crucial to the success of any food processing business. Our aim is to support our customers in improving their food safety knowledge and technology. We accomplish this by offering on-site training for their staff and contractors on the proper utilization of our cleaning systems.

Through this training, we ensure that all cleaning process steps are appropriately implemented, the cleaning program is validated, and the cleaning staff is well-informed about the essential aspects of food safety. Additionally, we are capable of assisting in the certification of your cleaning staff.

By following the simple steps and methods recommended by JBT Business Support Manager Niklas Landby, businesses can maintain their food processing equipment in optimum and food-safe conditions. By doing so, they can prevent the occurrence of foodborne illnesses traced back to their facilities and safeguard their customers’ health and their business reputation.

If you want to learn more about how inspections, suitable detergents, and on-site training can contribute to an efficient and hygienic food processing line, don’t hesitate to contact one of our food processing experts.