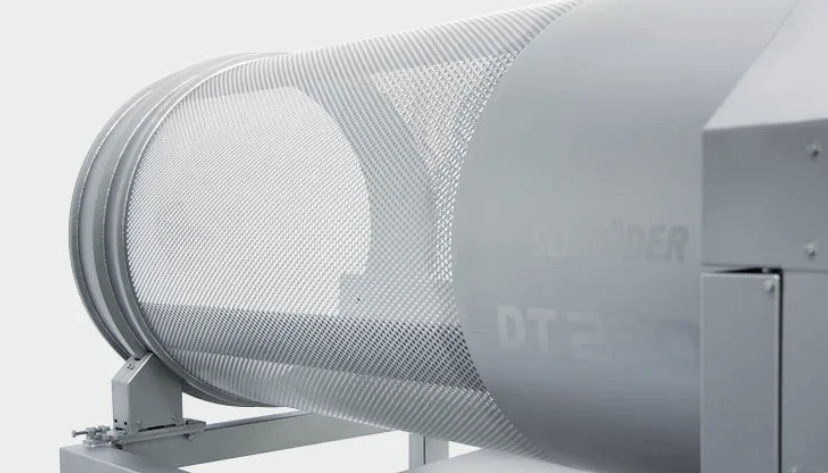

JBT Schröder’s DT 2500/3700 Continuous Tumbler is a game-changer for customers in the fresh meat, poultry and fish processing industries. Designed to remove excess brine and surface moisture, the DT Tumbler improves product quality, makes brine injection systems more sustainable, and saves time and energy when freezing.

Protein injection using Schröder IMAX Injectors comes with a range of benefits for protein processors from improved cooking and frying through to better water retention, improved product consistency and longer shelf life.

However, removing excess brine following injection equally has important benefits, and this is where the DT 2500/3700 continuous tumbler comes in.

Developed to meet specific protein customer needs and deliver exceptional results, the DT 2500/3700 offers a number of significant advantages for producing an ever-better product post-injection:

Enhanced Product Quality

The DT 2500/3700 tumbler is specially designed to massage fresh meat, poultry, and fish products, reducing excess brine and surface moisture. This results in improved product quality, making it ideal for processing poultry parts or whole chickens. By removing excess brine from the carcasses/surface, customers can ensure superior product quality for the further freezing process in one of JBT´s efficient and high-capacity Spiral freezers [link website].

Sustainable and Efficient

JBT understands the importance of sustainability in today’s world. That’s why the DT 2500/3700 tumbler features a brine collection system. Excess brine is collected and can be pumped back to the filter unit of the injector. This not only reduces waste but also ensures efficient use of resources, especially for customers with high injection rates.

Customizable and Adaptable

The DT 2500/3700 offers flexibility with its variable rotation feature. Customers can choose between right or left rotation to transport products. Additionally, the adjustable gradient and different baffle shapes create a continuous movement that is perfectly adapted to the specific product being processed. This level of customization ensures optimal treatment and consistent results.

Save on time and energy

JBT knows time is money for our customers. With the DT 2500/3700, they can save valuable processing time. In some cases, the need for second stage tumbling can be eliminated, streamlining operations and increasing efficiency. Moreover, by reducing surface moisture, the tumbler prevents rapid ice-build-up and icing in the freezer. This extends the production time of the freezer and saves energy, resulting in cost savings for customers.

Streamlined Production Process

The DT 2500/3700’s ability to reduce surface moisture is so effective that it can eliminate the need for a pre-freezer in certain processes. This means customers can achieve the desired results without additional equipment, further simplifying production process and reducing costs.

At JBT, we are committed to providing customers with innovative solutions that enhance their operations. The DT 2500/3700 continuous tumbler is a testament to our dedication to delivering high-quality, sustainable, and customer-centric products. Experience the difference it can make in your food processing operations today!

LEARN MORE about the JBT Schröder DT 2500/3700 Continuous Tumbler