Food recalls are every producer’s nightmare. Beyond the potential harm to customers’ health, the financial losses from unsold products, and the long downtimes in the production line, food safety issues can severely damage your brand’s reputation. That’s why hygiene should always be the top priority at any production facility. Since JBT started, we have acquired a deep knowledge of food safety and the conditions at food production sites. All our solutions are hygienic-by-design and easy to clean and maintain. As your committed partner, we are eager to help you improve hygiene in your food production line.

We provide food safe solutions across all your processes, including inspection, preparation, portioning, injecting, forming, coating, cooking, frying, freezing, high-pressure processing (HPP), and tray sealing.

Designing for Hygiene Excellence

At JBT, food safety starts at the drawing board. We design our equipment to minimize unnecessary surfaces and use as little material as possible to avoid dirt traps. We call this approach “Hygiene by Design,” which is especially important in food zone 1 where equipment has direct physical contact with products. It is also crucial in surrounding food zones where biofilm can increase the risk of bacterial growth.

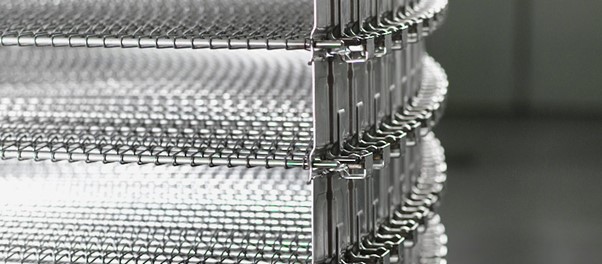

The Benchmark Freezer for Hygiene by Design

One example of Hygiene by Design is the Frigoscandia® self-stacking belt. This design builds a self-contained product zone, reducing structural parts, which means fewer surfaces to clean, less wasted water, and lower detergent consumption. Unlike other spiral freezers, there is no stationary rail support structure, eliminating collected debris and making cleaning easier. For the toughest food productions, JBT offers Fully Welded Enclosures (FWE), combining disinfection with hot steam sanitation. This design removes the risk of biofilm and microbiological growth in freezer units.

Precision and Safety

The Schröder product lines of IMAX stainless steel injectors for protein foods meet the highest standards of food safety. The external brine path is easily accessible and can be quickly removed for cleaning and inspection, ensuring products are not cross-contaminated. Additionally, the IMAX injectors allow for easy removal of needles, with all needles removable in less than 5 minutes.

Safety Without Heat or Preservatives

An effective way to secure food safety is the cold pasteurization technique developed by Avure HPP. This method uses ultra-high pressure purified water (up to 6,000 bar / 87,000 psi) to inactivate bacteria like listeria, E. coli, and salmonella. Neutralizing pathogens helps packaged foods stay fresher longer while preserving their natural nutrition, freshness, texture, and flavor.

Advanced Bone Detection for Safer Products

X-ray bone-detection systems, like JBT’s Innospexion system, play a crucial role in food safety. Finding and removing small bones from poultry and fish during processing has long been a challenge. Even though small, these bones can still cause abrasions, especially in children and the elderly. Innospexion’s advanced source and detection technology generates high-quality images, allowing for the accurate identification of fine bones in contrast to the meat.

Ensuring Consistent and Safe Operations

Regular inspections and preventive maintenance are essential for safe operations. By continuously monitoring machine performance, you can ensure that every application is treated correctly. Even a slight deviation in temperature can significantly impact product safety and shelf-life. JBT offers the OmniBlu™ service subscription, which connects JBT machinery for automatic monitoring and insights into performance. This also enables processors to maintain a history of processing operations, providing traceability in the event of a product recall.

Efficient Cleaning Solutions

Cleaning equipment is vital for food safety. JBT offers solutions specifically designed for fast, thorough, and economical manual and CIP cleaning of food processing equipment. Additionally, JBT has developed a series of detergents that meet rigorous legislative and customer requirements. All our products are designed to work within food production facilities, handling extreme temperatures and preventing bacterial growth. We also provide training in general food safety, HACCP, use of cleaning systems, and the design of equipment for sanitation.

By partnering with JBT, you can ensure that your food production line is safer, cleaner, and more efficient, protecting both your customers and your brand’s reputation. Find out more about JBT´s food safety solutions here.