Cutting pork bellies as preparation for bacon slicing has long been a labor-intensive process, plagued by frequent workplace injuries. However, prompted by an increase in worker absences as a result of the Covid-19 pandemic, many processors are now seeking a move to automation and JBT’s DSI Pork Belly Processing System offers a viable solution.

DSI Waterjet Portioning Systems are a proven means of improving product yield, reduce labor costs and increasing productivity; all factors that can be hugely beneficial to pork processors. Furthermore, the DSI systems can both increase product shelf-life and achieve a dramatic decrease in workplace injuries.

DSI waterjet applications for pork belly were developed in collaboration with a customer in the US and were found to be extremely effective in preparing pork bellies for bacon slicing.

New applications in Europe

While poultry has been the traditional application for DSI waterjets in Europe, DSI Business Unit Manager Roger Bosson says there has been a strong increase in demand for bacon slicing from Quick Service Restaurants. “Fast food restaurants often have a bacon option for burgers and that is driving demand for bacon across Europe,” he explains.

“Before cooking, processors need to prepare the bacon and increase the quality of the slice. We can do both by using the waterjet before the bacon-slicer. Coincidentally, we have also received more enquiries from the fast food industry about cooking options – such as JBT’s Contact Cooker – following slicing.”

Automation advantages

To date, a lot of pork and bacon preparation is still being carried out manually, but Bosson says many pork processors are now seeking to reduce costs and increase yield through automation.

A key example, he continues, can be found in the UK where pork processors – already affected by Covid-related employee absences – subsequently lost large sections of their workforce when Brexit came into force. As a result, many are now looking to automation as a cost-effective, efficient solution to meeting the labor challenges, while boosting yield and quality at the same time.

Minimizing work-related injuries

In the case of DSI Waterjet Portioning Systems, the advantages to pork processors are clear and proven. In addition to significant labor savings, the system can improve product quality by delivering a high level of consistently to the slicing process.

Further, the solution has major worker safety benefits. Bosson cites the case of a JBT customer who previously had people cutting by hand using knives: the result was at least one recordable injury every month. Automation removes this risk from the workforce.

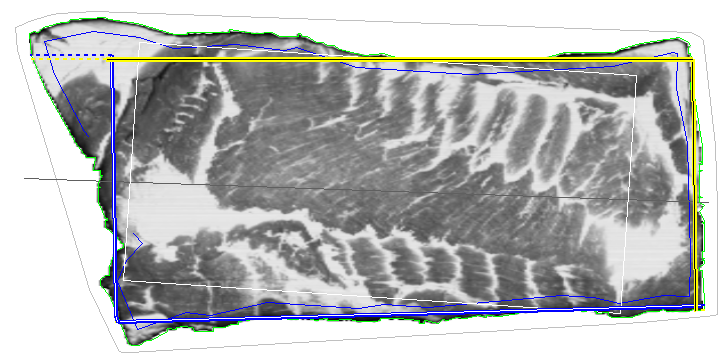

Shelf-life study

However, the benefits don’t end there. Bosson says the DSI Waterjet positively impacts both food safety and shelf-life. The evidence comes from a study carried out with a customer in Australia. During the study, it was found that significant levels of contamination took place when the pork meat was being cut manually on a line. The resultant bacterial contamination not only presented a food safety risk, it was also found to reduce shelf-life.

“If you cut fresh meat and have too many people handling it, it will get contaminated and the more bacteria contamination takes place, the less shelf-life you get,” explains Bosson. “every day of additional shelf-life makes a big difference. Therefore, reducing contamination translates into more shelf-life which means more money for producers and retailers.”