Tired of having to source processing line solutions from different manufacturers and having to learn how to make them work together? JBT is now offering a complete poultry preparation line solution for poultry processors, which offers unrivaled efficiency and effectiveness, enabling customers to achieve optimum quality for their products.

From bone inspection, flattening and tenderizing through to precise portioning and injection, JBT’s complete preparation line solution optimizes yield and removes human error, resulting in standardized, uniform products that live up to end customer expectations.

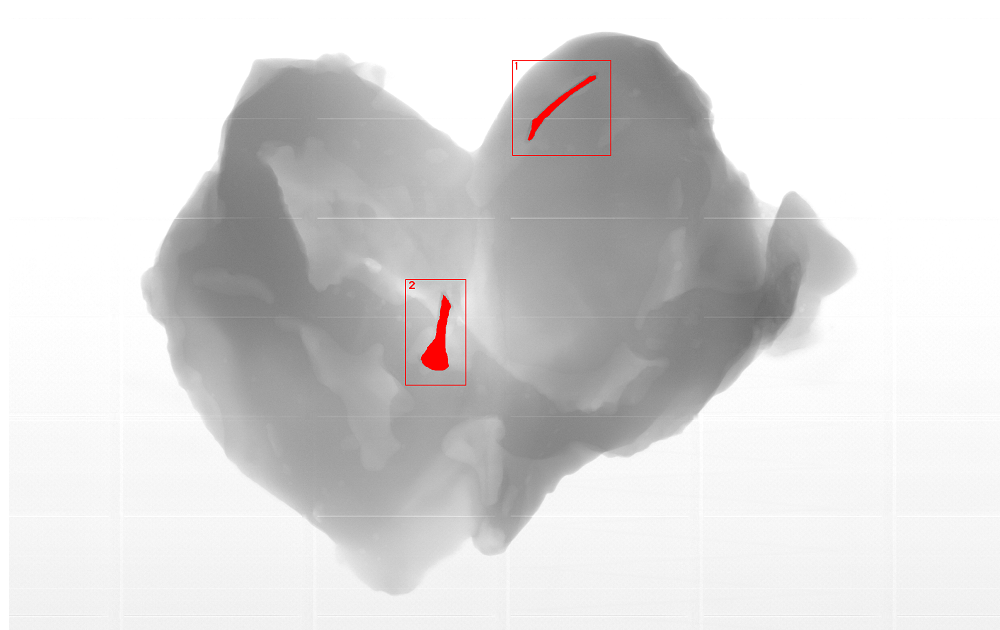

Unprecedented bone detection

The line solution begins with the cutting-edge JBT Innospexion bone detection system. This innovation reduces false rejects and the need for rework by using Long Wave X-ray (LWX) technology to detect even tiny differences in fillet thickness and density.

With a detection rate of up to 99% and a false rejection rate for calcified bones at less than 5%, Innospexion has a unique capability for simultaneous bone and foreign object detection, making it ideal for the inspection of deboned breast fillets, inner fillets, thighs, leg meat, and nuggets.

“By having the Innospexion system in the line, we can make sure customers have almost bone-free meat by determining whether there is any bone residue left after the de-boning process,” explains Roger Bosson, JBT DSI Business Unit Manager for the EMEA region.

Optimizing product thickness and uniformity

Following this, products move on to the alco Flattening Machine ASP, a solution designed to deliver homogeneous product thickness by using a number of rollers to press and stretch the meat.

“In many cases, the difference in thickness between for example the shoulder area and tail area of a chicken can be huge,” explains Bosson. “When you are trying to cut cubes and the customer wants them to be uniform in shape, cutting them from areas with different thickness is not as easy as if you even out the thickness before.

“The alco Flattener can be used to deliver a uniform thickness throughout a fillet without slicing it and losing yield because as soon as you slice products, you take away yield. Here, we are redistributing the meat. The Flattener evens out the thickness of the fillets, increasing the uniformity of final cut products in the process.”

Waterjet Portioning to maximize profits

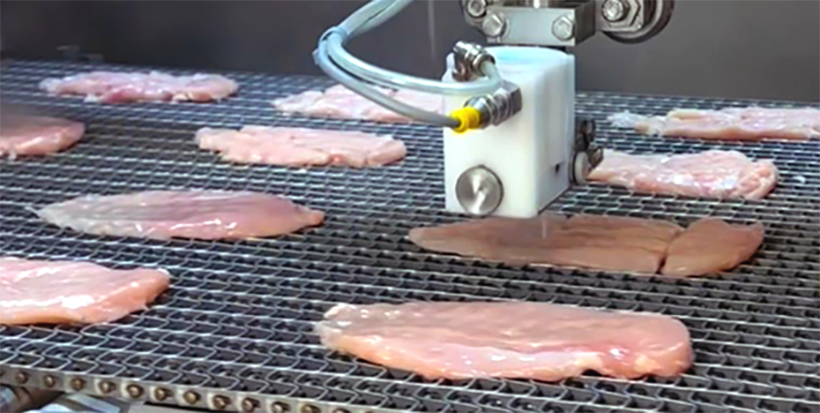

Once flattening is complete, the products can pass through an alco Tenderizer, before moving on to one of the final stages of the process, the DSI™ Waterjet Portioner.

Utilizing DSI Q-LINK™ Portioning Software, the DSI Waterjet Portioner creates a unique cut strategy for each individual piece of raw product to maximize yield and profits, determining shape, thickness and weight to create optimal cuts.

Having products with a uniform thickness also improves the quality of cooked products, allowing poultry to be cooked not just for the same amount of time, but for less time than would be required for thick pieces. As a result, it also lowers the instances of thinner products being overcooked on a line.

“When you overcook chicken pieces, you not only lose yield, you also lose quality and taste, and end up with a dry product,” continues Bosson. “Preparation of these products is critical for the cooking stage.”

For coated products, having pieces with a uniform thickness this is also hugely beneficial. “You will have more uniform pick-up – more uniform cubes have a uniform pick-up during the coating process,” adds Bosson.

Providing a more uniform product not only enables customers to reduce wastage while improving yield and quality, it also enables them to better meet client expectations, and benefit from repeat orders as a result.

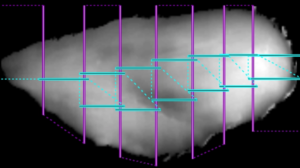

Further enhancing your poultry preparation, the DSI Adaptive 3D Portioning™ System (A3D) can assist by intelligently horizontal slicing breast meat to achieve higher yields when cutting lighter and thinner portions.

LEARN MORE about JBT’s Complete Preparation Line Solution for poultry