For protein processors, ensuring consistent quality and reliability can be a constant challenge. JBT Schröder understands these pain points and provides solutions specifically designed to address them. Whether you’re producing poultry, meat, fish, or plant-based proteins, Schröder’s injection and marination technologies offer the precision and efficiency needed to enhance product quality and streamline operations.

Processors often struggle with achieving uniform injection, especially with delicate products. The IMAX 620 from Schröder’s HIGHLINE series is designed to solve this issue. This walking beam injector transports the product through the machine via a rake system made entirely of stainless steel – extremely robust and hygienic. The high needle density and low injection pressure ensure gentle and uniform injection, even for sensitive products. This capability is crucial for maintaining the integrity of items like fish and poultry, while its adaptability to various product widths ensures consistent output across different food types. As a result, the IMAX Highline injectors can process nearly any product.

Optimized Massaging

Traditional tumbling processes can be time-consuming and inefficient. Schröder’s MAX technology offers a significant improvement, with up to a 50% reduction in processing times compared to conventional tumblers. The unique paddle design ensures a uniform and effective massaging action, enhancing system utilization and saving energy through increased efficiency.

Cost-Effective and Versatile Injection

Balancing cost with quality is a common concern for many processors. The IMAX 420eco C with belt transport system provides a solution by delivering Schröder’s trusted quality at a favorable price point. Its robust drive system and hygienic design make it easy to clean and maintain, reducing downtime and operational costs. With options for both bone-in and boneless products, it offers the versatility needed to accommodate a wide range of processing requirements.

Efficient Brine Management and Filtration

Managing brine effectively is essential for maintaining product quality and reducing waste. The FT 130/FT 200 filtration system supports the JBT Schröder IMAX ECOLINE and HIGHLINE injectors by supplying up to 200 liters of brine, while an external rotary filter ensures effective filtration. This system reduces operating costs by minimizing brine residue and allows for quick, tool-free cleaning. Its external rotary filter and quick-lock system allow for efficient filtration and easy cleaning, minimizing brine residue and ensuring consistent product quality.

Cost-Effective and Streamlined Brine Production

For processors looking to standardize and optimize brine production, the BRIMAX 600 offers a flexible and hygienic solution. The container size of 600 liters offers great flexibility in the production of different types. Proven components for the core functions, such as the mixing nozzle and rotary pump design, have been tried and tested for many years with the BRIMAX 1000 and BRIMAX 2000 models.

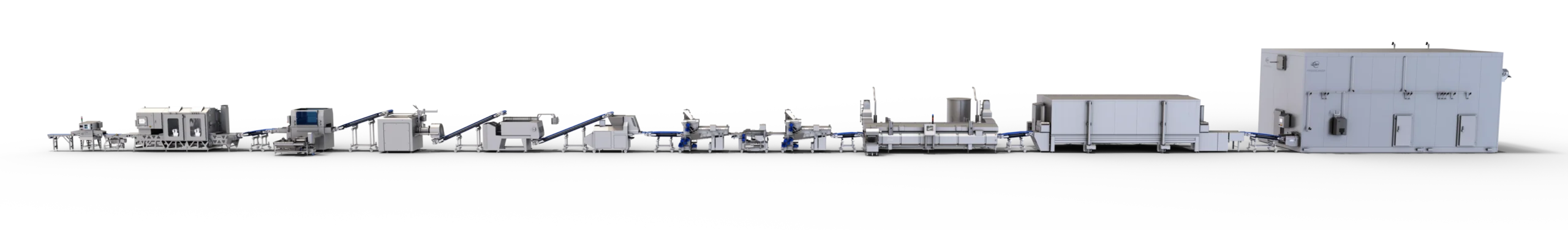

Tailored Solutions for Your Production Needs

Beyond the machinery on display, JBT Schröder is committed to helping processors assemble solutions that meet their specific production requirements. Through digital presentations and collaborative demonstrations at IFFA 2025, Schröder showcases how its innovative technologies can be tailored to address the unique challenges faced by protein processors.

Visit JBT Schröder at IFFA 2025 in Hall 8.0, Stand H44, from May 3-8 in Frankfurt, Germany, to explore these solutions firsthand and discover how they can transform your operations. Visit our IFFA webpage to learn more about our showcasing scope: jbtc.com/foodtech/visit-us-at-iffa.