Looking for a new, more effective way of carrying out poultry processing? JBT has introduced new and innovative technologies for poultry processors, which offer comprehensive solutions to enhance efficiency, quality and profitability.

At Anuga FoodTec 2024, JBT’s leading solution players including Innospexion, alco, DSI and Schröder are set to unveil a complete line-up of groundbreaking systems, delivering yield improvements at every stage of poultry preparation.

“With the combination of inspection, preparation, portioning and injection solutions, we are now able to offer a much more complete processing line,” says Roger Bosson, JBT’s Business Unit Manager for the portioning and x-ray portfolio.

“They are all contributing in their own way to optimize the yield and prepare products before further processing,” “It’s all about increasing the value of the product for the customers in the smartest possible way.”

Bone Detection solved: multiple benefits with Innospexion

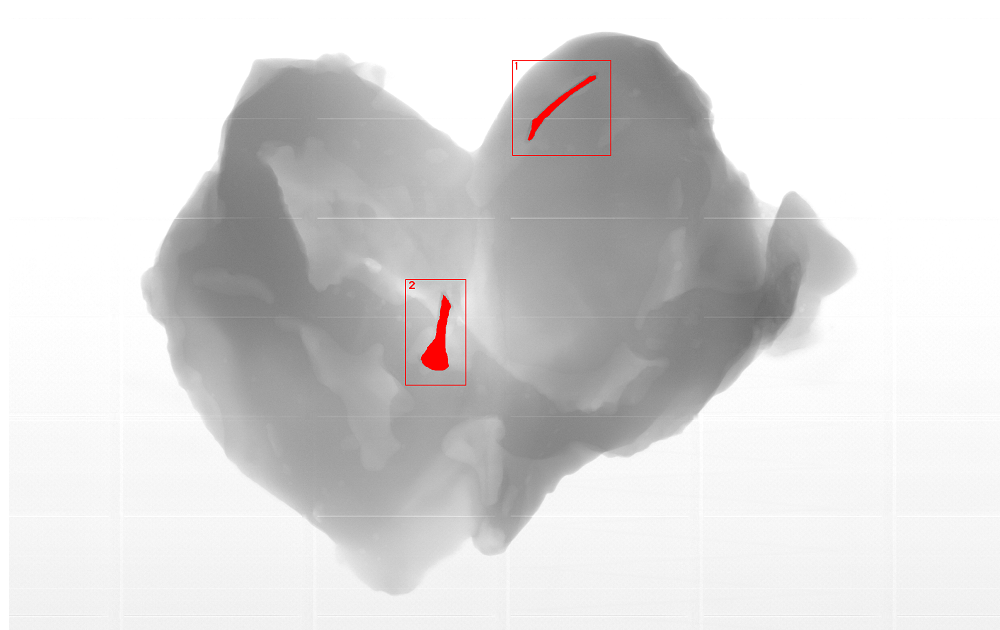

Aiming to maximize poultry yields and stop throwing away good meat as a result of haphazard bone detection systems? JBT Innospexion is a solution that offers unparalleled accuracy when it comes to finding bone fragments, allowing processors to retain the greatest amount of product after reworking.

With a 98% bone detection rate and a less than 5% false reject rate for calcified bones down to 2mm x 2mm x 2mm, the unique, innovative JBT Innospexion system is the perfect solution. Capable of locating small, calcified bones or bone fragments in poultry and fish, Innospexion guarantees a high, reliable bone detection rate without unnecessarily rejecting products from the line.

“With the highest detection rate in the market, we scan the fillets to confirm there is no bone residue in them and this results in both higher quality and less labor,” explains Bosson. “Innospexion has found a way to much more accurately locate pieces of bone in fish and poultry. By integrating Innospexion at the beginning of the production line, processors can streamline rework processes and minimize labor, maximizing both quality and yield.”

“If you can see where the bone is, it makes it much easier to take it out when the product is sent to the rework stations, so it speeds up the whole rework and trimming process,” continues Bosson. “Previously, workers had to try to feel where bones were located. With Innospexion, they can see where the bone fragment is, so they can minimize the trim.”

Preparation solutions from alco: poultry done right

Complementing the precision of Innospexion, the JBT alco Flattening Machine ASP and Tenderizer ASC deliver uniformity and tenderness to poultry products. Many processors need to achieve uniform product thickness and enlarge product surface, and this is where the alco Flattener (pictured below) comes into play.

Natural products, which usually have an uneven shape and thickness, are flattened to a homogeneous product thickness in order to achieve a constant cooking time with lower cooking losses. Over 30 years of development have gone into today’s flattener, making it the best system in its category.

In addition the alco Tenderizer improves product tenderness by applying small incisions to the meat surface. This brings even more flavor to the product as it allows marinades and spices to be absorbed into the meat. JBT alco provides the best conditions for preparing boneless products.

Get your profitability into better shape with DSI

Experience a shift in portioning flexibility and efficiency with the new compact and intelligent JBT DSI™ 812 Waterjet portioner, which allows customers to get up to 25% more yield and maximize utilization, throughput and flexibility. With its compact design, the 812 fits right into a production line and perfectly complements the preparation and yield improvement solutions for poultry products.

The JBT DSI 812 (pictured) gives you total control over your poultry portioning, enabling you to reach high weight and dimensional specifications requirements and maximize yield and utilization. Take your portioning inline and boost your throughput, remove the risk of human error, and utilize your workers in other areas with the fully automated and intelligent 812 waterjet portioner.

If you are curious about how the DSI 812 can make your portioning process more efficient, intelligent, and profitable? Book a demonstration with our experts at Anuga FoodTec.

Schröder solution for better taste

To complete the raw preparation line, Schröder’s IMAX 630 injector (pictured) injects brine for taste, yield optimization and pick-up. Featuring product-specific stitch patterns, needle design and individually-adjustable injection pressure, the IMAX 630 ensures precise and even injection.

It comes with adjustable injection rates and the highest injection accuracy. The outstanding hygienic design provides reliable, sustainable and proven results, elevating the taste and quality of poultry products.

JBT will be exhibiting at Anuga FoodTec 2024 in Hall 6.1, Stand D090 F119 from March 19-22, 2024 in Cologne, Germany and you will be able to see all of these solutions first-hand.

Download the floorplan for a sneak-peak and book a demonstration today!