The invention of Individual Quick Freezing (IQF) and the installation of the first IQF freezer, which recently celebrated its 60th anniversary, marked a turning point for the modern food industry and with it JBT Frigoscandia achieved one of the most important milestones in the history of frozen food convenience and product quality worldwide.

Today, we may take the quality and convenience of frozen food for granted, benefiting from systems that allow us to defrost only the amount of product we need for a given meal, but such convenience wasn’t always the case.

“The first FLoFREEZE® IQF Freezer was installed in 1962; before that, companies had to block-freeze, so when shoppers bought frozen vegetables, they bought a block of ice,” says JBT Frigoscandia’s Joakim Fajerson who is responsible for Application Technical & Sales Support Customer Care for the EMEA region.

“The FloFREEZE was a revolution for the food industry. It allowed customers to take out the quantity of frozen food they wanted from the freezer rather than having to defrost a block and have to throw away anything they didn’t want to eat.”

Devising a solution

The story of the FLoFREEZE and IQF freezing began in 1959 when Frigoscandia engineers Per-Oskar Persson and Leif Hanérus were tasked with devising a new freezing system from a UK customer that moved away from the previous system of “block freezing”, where products – mainly peas – were frozen in a literal block before being broken up with a so-called “Cluster-Buster”. The practice of smashing a frozen block apart by brute force was crude, inefficient and above all left behind a huge amount of damaged and wasted products.

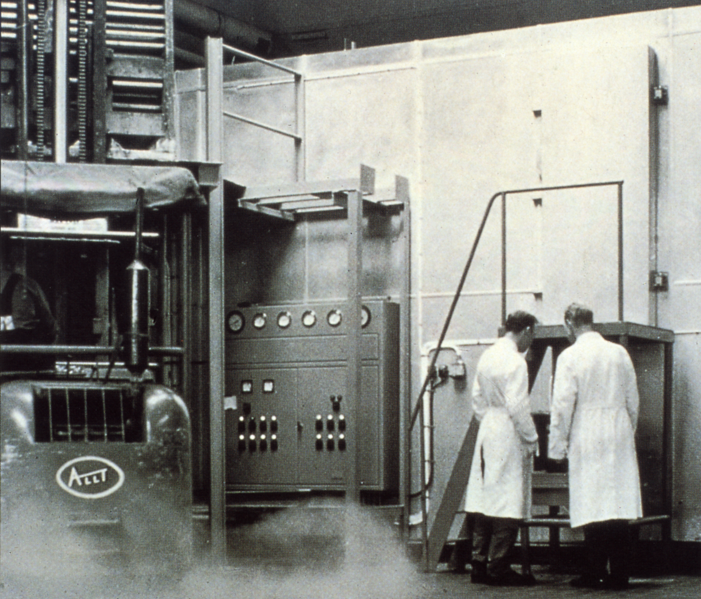

Per Oskar Persson demonstrating the FLoFREEZE fluidization principle.

The problem Persson and Hanérus faced was creating a solution capable of handling chicken in the winter months and peas during the summer in the same unit, and without doing the damage associated with block freezing. The solution they devised was ingenious.

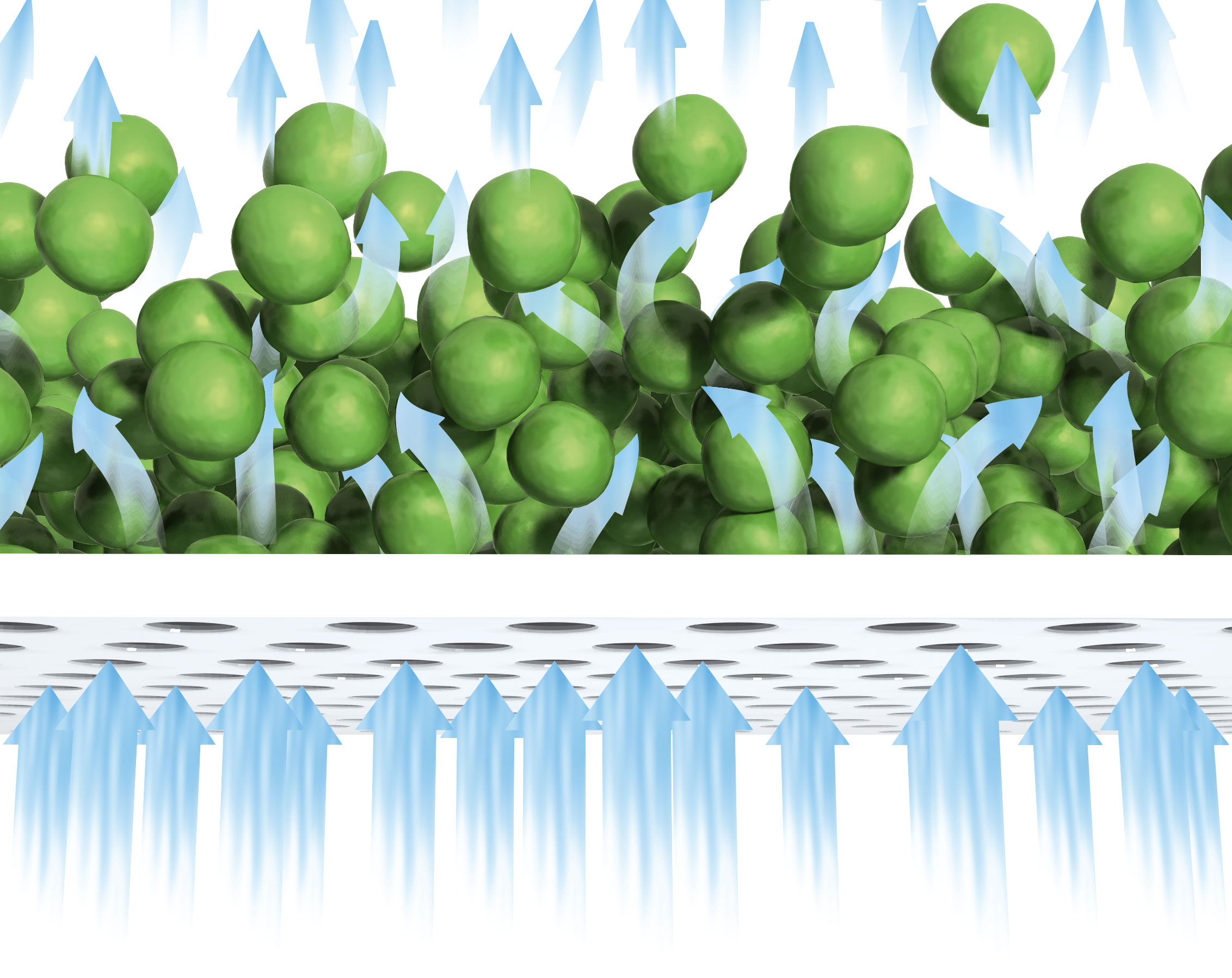

First piloted in 1960 in Helsingborg, Sweden after extensive development including trials in a bathtub, the Frigoscandia FLoFREEZE was the world’s first freezer to use fluidization for IQF. Based on the principle of capturing the freshness of peas during the freezing process, the IQF system was created to lift products in an airstream as they entered the machine before freezing each piece individually.

Beginning with vegetables, the scope and range of the FLoFREEZE has grown in the 60 years that have followed to encompass seafood, small fish, minced meat, pasta, berries, rice, cheese toppings, and shredded, diced or cubed chicken.

A better way of freezing

The system, according to Lars Michael Svensson, Regional Sales Support Manager for JBT Frigoscandia, has been so successful that it can individually freeze almost any product as long as it’s light enough to be carried by the airstream. The FLoFREEZE, he continues, has also acted as a stepping stone for many customers who move on to GYRoCOMPACT Spiral Freezers when they want to offer frozen breaded, marinated or battered products.

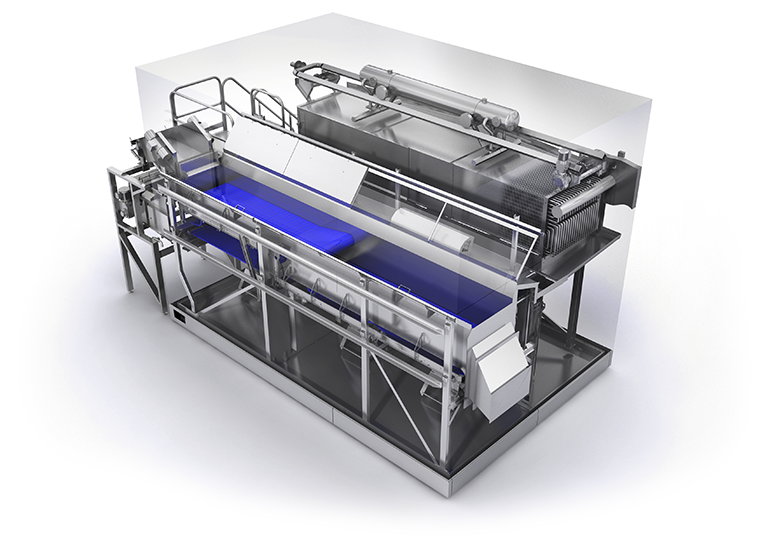

But what has the FLoFREEZE (pictured below) meant to the food industry in the decades since its launch? Joakim Fajerson is clear: “You get a better product. Although you weren’t dependent on the seasons either with block freezing, it is much more convenient with the FLoFREEZE. It also makes it much easier to create frozen product mixes by bringing together different items, such as an Asian mix or whatever is in demand at that moment.”

“To freeze a block of products takes a long time,” continues Svensson. “If you do it one-by-one, it’s much quicker. This means that with the same footprint, the capacity could be dramatically increased. We know that frozen products keep more nutrition inside them, so there are many benefits with the FLoFREEZE.”

Svensson says the system also gives customers huge flexibility. “They can run for example cauliflower rice, which are cubes of cauliflower diced down to 4x4mm and in the same machine, in the afternoon, they can do cauliflower florets instead, and there’s a big difference in size and shape,” he explains. “And next day, they can do strawberries, then the next, shrimps. So there is huge flexibility on the same machine.”

“And it’s still the most efficient way to freeze these products – even after 60 years.” However, there have been multiple improvements to the FLoFREEZE design over the decades. One example is from the 1990s, a significant breakthrough occurred when we merged two separate FLoFREEZE freezers, the tray freezer and belt conveyor freezer, into a single unit that could agitate a belt conveyor. This meant that customers only had to purchase one freezer to handle all types of products, instead of the previous requirement of buying two.

In conclusion, the FLoFREEZE IQF freezer has transformed the food industry and marked a turning point for the modern food industry. With its ability to individually quick-freeze products, the FLoFREEZE has brought convenience and product quality to frozen foods. Even after 60 years, the FLoFREEZE remains the most efficient way to freeze these types of food products, and its story will continue to run and run.