Looking to increase the yield of your poultry operation while also saving on labor costs? The new JBT DSI 812 Compact Waterjet Portioner and Innospexion Bone Detection X-ray system offer cost-effective options for small-medium sized processors to boost poultry yield at the same time as delivering a solution to labor shortages across the industry.

For many poultry processors worldwide, sourcing adequate labor for an unattractive manual job has become challenging over recent years. At the same time, many companies are seek to increase yield to get more value and premium products out of the raw materials.

The combination of the DSI 812 with the Innospexion Bone Detection X-ray system can meet both objectives with the added bonus – in the case of the 812 – of offering greater flexibility in terms of simultaneous product portioning.

Greater portioning flexibility

At the upcoming Gulfood Manufacturing trade exhibition, which runs from November 7-9, 2023 in Dubai, JBT will highlight why the flexibility provided by the DSI 812 is not just attractive for smaller processors, but has also proved useful for larger poultry companies.

“We’ve seen that instead of buying a single large machine, some customers are choosing two smaller portioners and placing them side by side because this allows them to have greater flexibility,” explains JBT business unit manager for DSI in the EMEA region, Roger Bosson.

This option, he says, effectively allows customers to run two portioning lines at the same time, independently of each other. “Some customers are using two 812 two-cutter machines rather than a single, four-cutter machine because then they can produce one product in one of the machines and another in the other at the same time,” Bosson adds.

Plug-and-play to increase yield

A further advantage offered by the DSI 812 is its potential to effectively replace blade cutters.

“The solution is so compact that it has the same footprint as a blade portioner, but with much higher flexibility and yield,” continues Bosson. “As an example, if you cut chicken strips with a blade portioner you can maybe reach 70-75% yield. With the DSI 812, you can achieve as high as 85-90% yield. That extra 10-15% yield pays for the machine quite quickly.

“The DSI 812 has a higher yield and a greater flexibility, so there are many advantages that come with that.”

A further advantage of the 812 is a design which integrates the system pump into a single machine. While previous models have had a separate pump that has to go into separate utility room, the 812 is a ‘plug-and-play’ unit, which can be installed in two-three hours.

Making a difference in bone detection

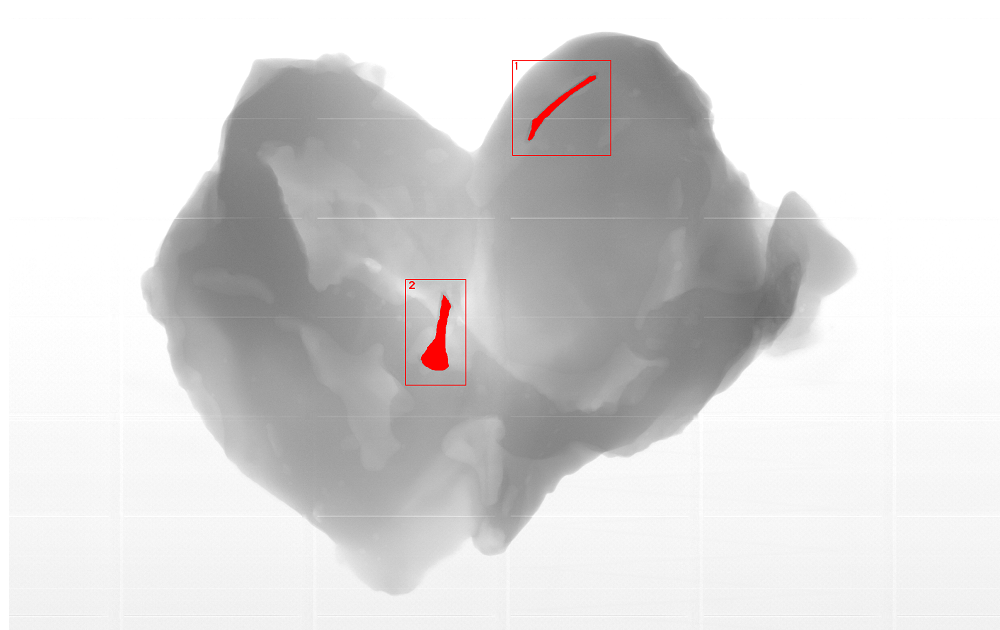

The Innospexion X-ray system, which offers a superior solution for bone detection in poultry and fish, offers a complimentary, labor-saving technology to the 812, thanks to its low false-rejection rate. This helps customers increase yield and save on secondary-processing manual labor.

“The Innospexion system finds the bones in a better way than existing technology and we can indicate where that bone fragment is very precisely in the fillet, so the person who is cutting it out doesn’t have to cut out more than necessary,” explains Bosson. “Before people used to cut substantially more than they had to, resulting in a lower yield and wastage of perfectly good products. With the Innospexion technology we can very clearly see on a screen where to make the cuts.”

Overcoming the labor challenge

In the Middle East, Bosson believes the DSI 812 and the Innospexion system have the potential to transform the business for many food producers. “Although we have many machines in the region, particularly for larger processors, the industry is suffering from a shortage of labor because no-one wants to do this cold and wet job anymore,” he says.

“Also, if we look at cutting cubes for example, manual labor can cut maybe 30 kilos an hour; the DSI 812 can do 500 kilos in the same timeframe. It would take on average 17 people to produce the same output, whereas the 812 can run we three people at the most.

“On top of that, you get a better yield and a better uniformity of the cubes.”

In summary, the DSI 812 and the Innospexion X-ray system offer as a solution – individually or together – that has a proven effectiveness in increasing yield while also helping alleviate labor shortages. In the process, the solutions can make ramping-up poultry production a reality.

JBT will be exhibiting at Gulfood Manufacturing in Hall 4, Stand D4-42 in the Dubai World Trade Center from November 7-9, 2023.

LEARN MORE about the DSI 812 and the Innospexion Bone Detection X-ray system