Aiming to get more out of your smoked or dry sausage operation? JBT Tipper Tie, a leading global supplier of processing and clipping machines for sausage and whole hams, will be showcasing the effectiveness of its TTStick Automated Hanging System for not just streamlining operations, but also for helping customers get up to 25% more product into their smoke houses and drying rooms at the upcoming Anuga FoodTec 2024 trade exhibition.

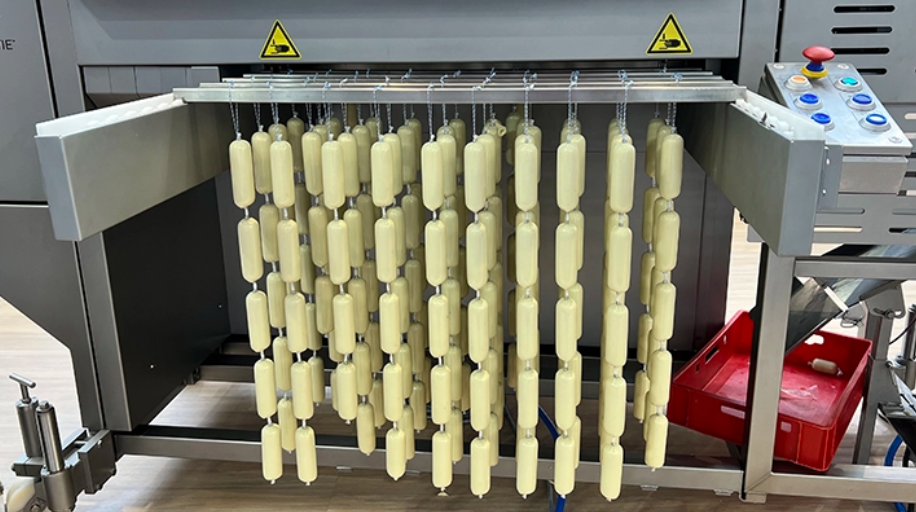

With a simple yet effective automated suspension technology, the TTStick is the latest in Tipper Tie’s successful line of high-speed Automated Hanging Systems. Up to 100 loops per minute can be hung and will form part of a working line at the show together with a TT1512 Automatic Double Clipper.

Visitors to Anuga FoodTec, which runs from March 19-22 in Cologne, Germany, will also be able to see the SVU6800, Tipper Tie’s latest Automatic Double Clipper for whole muscle or large products, including those using difficult-to-run spice casings.

Boosting productivity

Combining state-of-the-art automated suspension technology with highly intuitive, user-friendly controls, the TTStick delivers labor savings, reduces ergonomic issues, and increased productivity with the ability to improve sausage quality by reducing human intervention during the production process.

According to JBT Tipper Tie’s Director of Product Management, Conrad Faust, the technology allows customers to put more sausages on a smoke stick, while maintaining optimum spacing meaning they can get more product into drying rooms and smoke houses. Such an option, Faust says, is hugely important for producing hung products such as salamis and pepperonis.

“If you are doing a dried sausage, which has to spend a certain amount of time in a drying room, plants will become constrained by how much product they can fit in those rooms,” he continues. “Even with a customer doing smoked sausages, they are constrained by how much meat they can get into the smoke house.

“By allowing our customers to get more product in the smoke house or drying rooms because we have taken that human element out, they can – in a lot of cases – increase their production. As space is the bottle neck in smoke houses and drying rooms, 25% more product on a rack can have a very big impact for our customers.”

In fact, the removal of the human element is a further benefit provided by the TT Stick, Faust explains. With much of salami production dependent on the growth of beneficial molds on the sausage, any kind of handling of the product can affect the product. It can also lead to inconsistent spacing of the hung sausages. “The less handling, the less human intervention, the better for truly high-quality salami production,” Faust adds.

JBT Tipper Tie will be exhibiting at Anuga FoodTec 2024 in Hall 6.1, Stand D090-F119 from March 19-22, 2024 in Cologne, Germany.