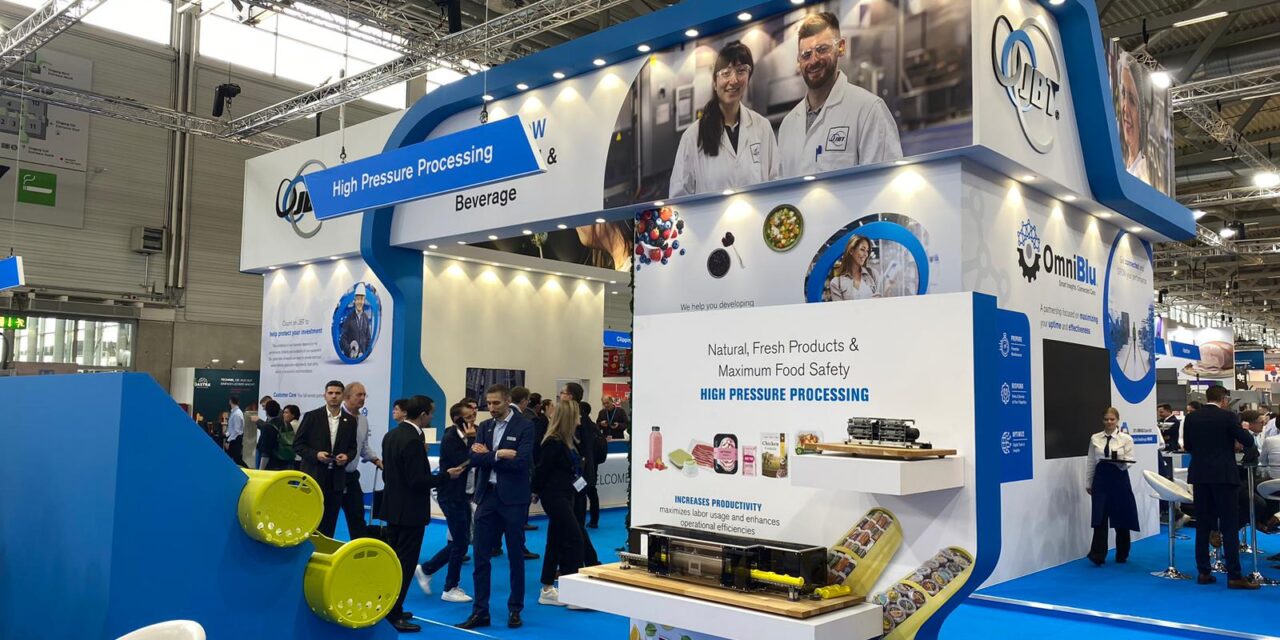

JBT’s presence at Anuga FoodTec 2024 was very successful in terms of showcasing a broad, leading portfolio and a range of technologies and solutions helping drive innovation across the food and beverage industry. Visitors and customers were particulary impressed by the breadth and depth of our portfolio and equipment on display.

Anuga FoodTec provided a great opportunity to promote cross-selling opportunities and combined technology. One of the highlights of our presence was the ability to present our full line solution concept. This concept showcased our ability to provide end-to-end solutions that streamline production processes and enhance efficiency. The integrated approach received positive feedback from attendees, who recognized the value of having a single provider for their digital needs.

With some 40,000 visitors from 133 countries and a combined 133 exhibitors, Anuga FoodTec once again underlined its importance as a both a gathering place for the global food and beverage industry and an ideal forum to showcase innovations.

Here’s a few of JBT’s highlights from the 2024 edition:

JBT alco wows with solutions that fit every budget

During its introductory visit to Anuga FoodTec as part of JBT, alco offered customers the opportunity to learn more and better understand the quality and features present across all its solutions.

A versatile all-rounder, the alco HotCook is capable of mixing, cooking, braising, reducing, and re-cooling a wide array of culinary creations, from sauces to ready meals and stews.

Thanks to different parameter settings, the machine can be optimally adapted in a highly flexible manner for overall product quality and energy consumption.

With labor-saving solutions high on visitors’ wishlists, alco was able to showcase its ability to combine effective automation with consistent quality and uniformity across a range of solutions, including the alco Flattening Machine and the alco Tenderizer.

Taking imprecision out of the equation, the solutions impressed visitors with their capacity to deliver products with a uniform thickness that can effectively absorb flavor for better-tasting, more consistent final products.

DSI and Innospexion: innovations helping get the best out of poultry

Another debutant on the JBT booth was JBT Innospexion, the groundbreaking bone detection system which finds even the tiniest bones, preventing good product from being thrown away and maximizing yield in the process.

With a 98% bone detection rate and a less than 5% false reject rate for calcified bones down to 2mm x 2mm x 2mm, Innospexion can locate small, calcified bones or bone fragments in poultry or fish, helping ensure that processors retain the greatest amount of product after reworking.

DSI’s compact and intelligent 812 Waterjet Portioner is another solution developed to maximize yield and minimize unnecessary waste when it comes to poultry processing. The DSI 812 is not only compact by design, it also enables processors to increase yield by up to 25%, thanks to optimal cut strategies that generate complex, tailor-made shapes in a single pass.

Featuring DSI Q-LINK™ Portioning Software, the solution helps boost throughput while removing the risk of human error and allowing companies to better utilize their workforce.

Schröder brings winning automation and hygiene combination

For any companies working with poultry, meat or fish, it goes without saying that food safety and hygiene is of prime importance when it comes to protecting reputations and avoiding costly recalls.

At the same time, labor shortages and energy-price rises are putting processors under pressure like never before, driving an increasing movement towards automation throughout the industry.

JBT Schröder, the specialist in injection and marination solutions, is at the head of the field in terms of providing innovative, automated systems that guarantee the highest levels of efficiency and hygiene.

A good example is the Schröder IMAX ECOLINE injector –- ideal for small and medium-sized companies. IMAX ECOLINE injectors do not require any labor during operation and can be cleaned quickly thanks to a well thought-out hygiene concept. High-quality materials and a robust drive concept ensure the longevity of the machine.

Featuring adjustable injection rates, the highest injection accuracy and an outstanding hygienic design, the IMAX 630 Injector – which was on display at the JBT booth – delivers reliable, consistent results, elevating the taste and quality of meat and even fish products.

In addition, with the MAX massaging systems, JBT Schröder offers efficient marinating technology with significantly shorter processing times than alternative systems, both for smaller quantities of up to 600 kg and large product quantities of several tons per load.

Tipper Tie: increase productivity without compromising on quality

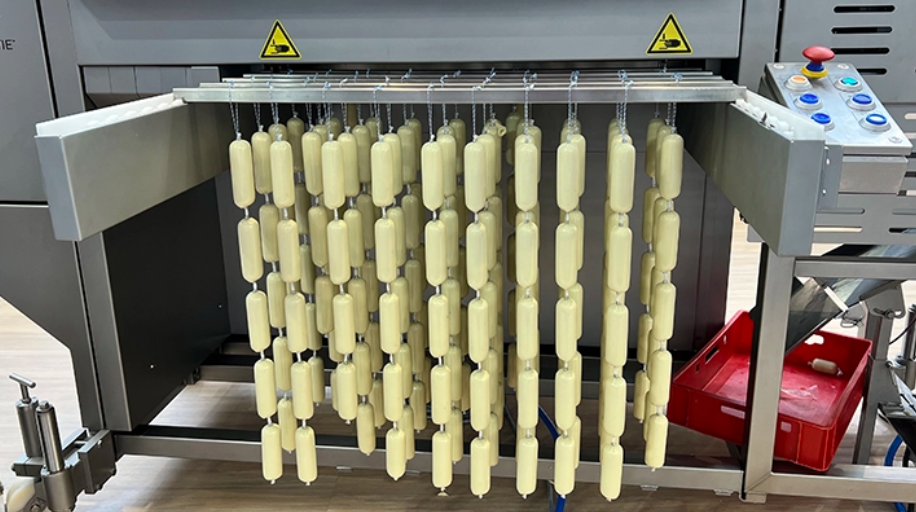

For customers involved in the smoked or dried sausage business, JBT Tipper Tie’s range of highly-effective automated and semi-automated solutions deliver optimum results while enabling customers to save on labor and avoid potentially-costly human contamination.

In the case of smoked or dried sausages, human contamination caused by any kind of handling can significantly impact the delicate development of product quality. This is why Tipper Tie’s TT Stick – which was on show at the JBT booth – can add huge value for customers.

As visitors could see, the TTStick allows customers to get more product into smoke rooms while removing the inadvertent impact of handling on the sausages.

Other equally effective solutions highlighted at the event included the TT1512 and TT1815 Automatic Double Clippers, the result of years of systematic product development that represent the finest quality in modern closure technology.

Both solutions enable enable customers to increase productivity while moving operators to sections of the line where they can be more effective.

The GC40: Compact, efficient and unrivaled in its effectiveness

Last but far from least is one of JBT’s best-selling solutions. The Frigoscandia GYRoCOMPACT self-stacking spiral freezer is the most compact, hygienic and efficient spiral freezer ever made.

With freezing capacities of up to 1,000 kg/hour, visitors to Anuga FoodTec were able to learn how the CG40 offers unrivaled energy efficiency and freezer power consumption, as well as the unique FRIGoBELT® Nova self-stacking belt that forms a closed freezing zone to eliminate the risk of products moving by horizontal airflow.

Not only cost-effective and compact, the GC40 delivers efficiency and Return on Investment, plus it comes with all the same winning JBT features of a larger machine.

These were just a few of the many highlights from Anuga FoodTec 2024. Until next time, you can continue to keep up to date by subscribing to the JBT Protein Blog!