Massaging is a technology offered by JBT Schröder to achieve higher production yields and easier handling. Tumbling systems found in many areas of the protein industry are similarly used to distribute brine and other marinades and improve color stability. In this blog post, we’ll take a deep dive into the world of meat marination, comparing two popular technologies – tumbling and massaging – to find out which one is the best bet.

JBT Schröder Sales representative and meat technologist, Günter Breitbach (pictured) explains what the process involves, how the technologies differ and why the massaging technology make such a difference.

JBT Schröder Sales representative and meat technologist, Günter Breitbach (pictured) explains what the process involves, how the technologies differ and why the massaging technology make such a difference.

The benefits of marinating

Do you know how your favorite cuts of meat get that mouth-watering flavor and texture? The answer lies in the marination process, and the technologies used to achieve it. Both massaging and tumbling systems are used to distribute brine and other marinades in meat (e.g. cooked ham), poultry, fish, and seafood products.

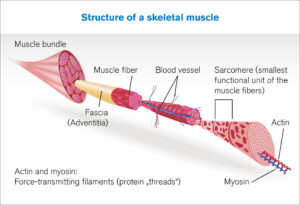

When meat is injected with brine and other marinades, it helps to hydrate the meat, add weight and flavor, and create a more cohesive end product that can be easily sliced without falling apart. But, the effectiveness of the water retention and protein activation during the processing stage is crucial to the quality of the final product. This is where tumbling and massaging technologies come in.

How the systems work

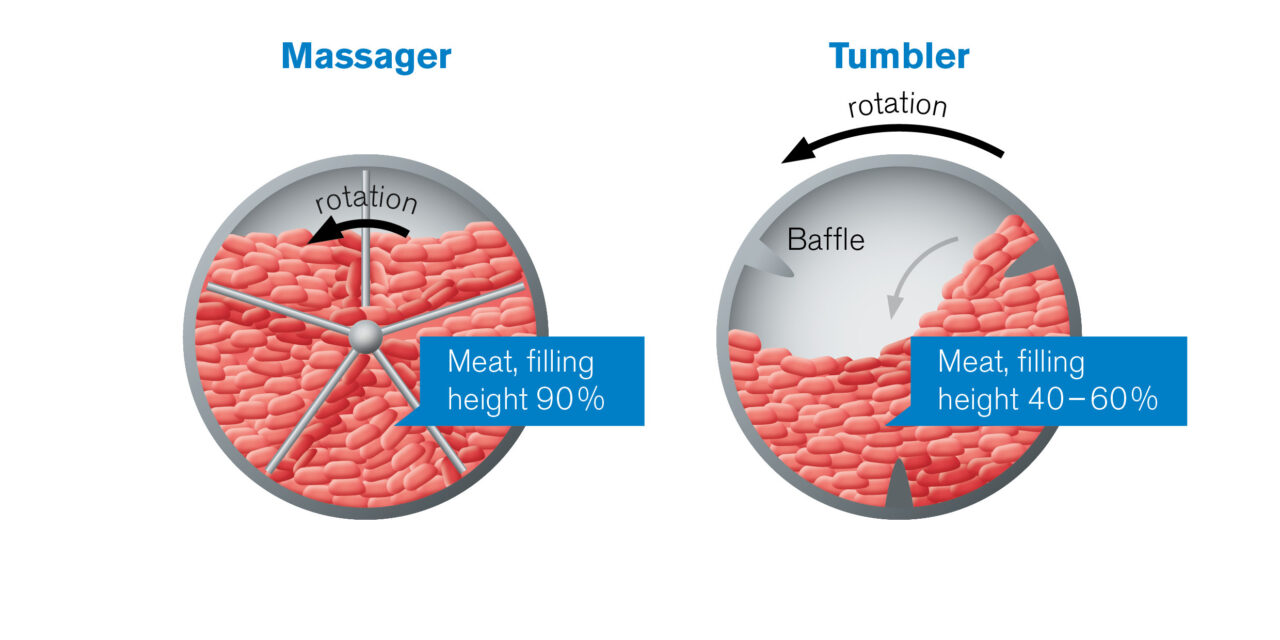

Tumbler technology involves rotating the product horizontally in a large drum on guide rollers, while flat baffles on the inner walls of the container cause the pieces of meat, poultry or fish to fall in a gentle movement. This movement is also commonly known as “rumbling”.

In contrast, massaging – as offered in the form of Schröder’s MAX Massaging technology –takes a completely different approach. Here the container has a fixed construction with an internal, rotating shaft. Large, spiral-shaped paddles mounted on the shaft move the product around its axis. Unlike tumbling systems, the massager’s paddles move within the meat mass, meaning there is not just contact between the product and unit at the outer edge, but that each individual muscle is actively touched.

Yield and cost-saving differences

Compared to tumbling systems, the MAX Massager can reach up to 90% fill volume, almost doubling the amount of final product that can be produced. The massager also offers important cost-saving advantages.

Using up only one-third of the free, unused volume of a tumbler, the massager builds up a vacuum in a considerably shorter time than a tumbler, saving on energy in the process. Plus, thanks to the strong mixing action of the paddle combined with a large, effective contact surface with the cooled vessel container wall, the interior temperature of products are quickly and effectively reduced.

Demonstrably better results

While tumbling systems passively cure the product, the MAX Massager actively incorporates the brine into the muscle by causing muscle fiber to expand, intensified by the vacuum in the container. As a result of the high pressure achieved by the large paddle and the high fill level, the massager delivers a direct, active input of mechanical energy into the core of the individual muscle. The consistent 1°C temperature with the MAX massager results in protein activation – the key to optimal water retention as well as a higher yield at the slicer.

The demonstrably better results achieved using massage technology can be seen in products showing higher protein activation within a shorter period of time, resulting in better overall yields. The MAX’s improved slice firmness also delivers a higher slice yield.

The established industry standard

Available in sizes ranging from 600 to 6000 kg nominal fill volumes, the Schröder MAX Massager has established itself as the most effective technology for bone-free products to the point that it is used by around 70% of the German meat industry today.

The most recent iteration, the MAX 600 compact massager (pictured above with the MAX 1200), with integrated cooling and vacuum pump, represents the ideal entry point into the Schröder massager program. A “plug and play” solution for batches of up to 600kg, the MAX 600, like others in the range, offers a high efficiency massaging technology for curing and marinating, delivering more tender and juicer final products that meet consumers’ expectations.

In summary, if you’re looking for a way to improve your production yields and create a more cohesive, flavorful end product, consider the JBT Schröder MAX Massager technology. Its active incorporation of brine into muscle fiber, high pressure, and efficient cooling and vacuum pump make it a top choice for the meat, poultry, fish, and seafood industry.