When it comes to the industrial bakery industry, freezing products to make them suitable for storage and transportation can be a costly and inefficient process. Huge amounts of energy have to be expended to remove heat from products, and temperature loss is common as refrigerant is pumped along lengthy piping to freezers.

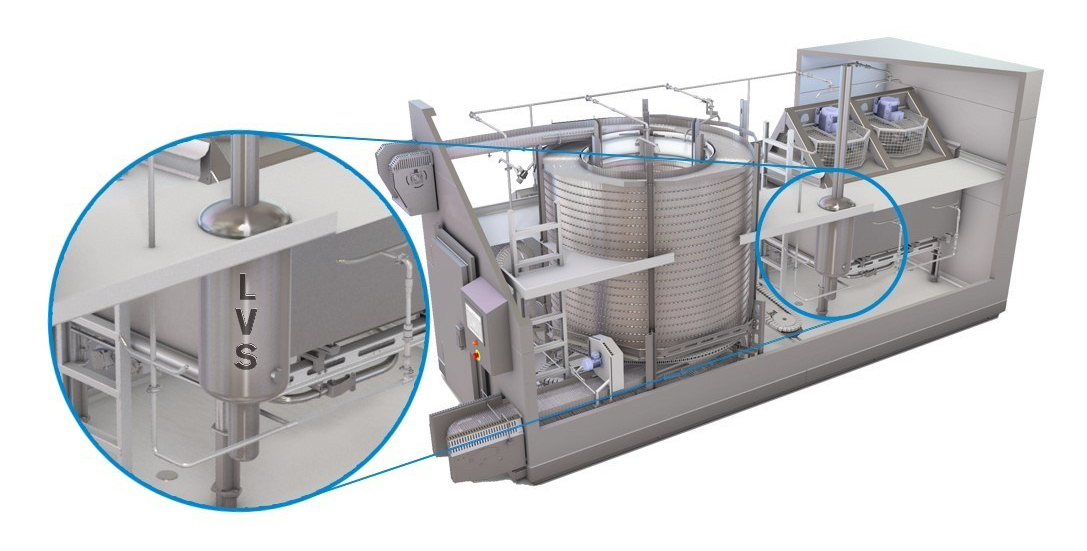

JBT Frigoscandia’s Low Volume System (LVS) Refrigeration units are up to 20% more efficient than traditional pumped refrigerant systems, thanks to a patented dry suction system that delivers more capacity from the compressor and enhanced evaporator performance, adding up to greater freezer capacity and energy savings.

A Partnership That Bakes Success

Our success story begins with a renowned bakery customer in Europe, a long-time operator of Frigoscandia GYRoCOMPACT spiral freezers. This progressive bakery customer has always championed energy-saving initiatives, and the introduction of the LVS system has taken their commitment to the next level. By optimizing their refrigeration plants, the LVS has enabled them to harness temperature generation more efficiently than ever before.

“The LVS is enabling the customer to utilize the temperatures generated by the refrigeration plant in a more efficient way,” explains JBT’s Sales Manager, Jan Grundmann. “Thanks to the LVS, they can now run their refrigeration plant at higher temperatures, resulting in a remarkable reduction in energy consumption and CO2 emissions.”

Solving The Temperature Loss Problem

One of the energy and capacity challenges faced by industrial producers is temperature loss during the refrigeration process. Grundmann explains how the refrigeration feed typically works at customer sites: “The connected freezer and refrigeration plant is often placed far apart which means that the cooling agent needs to be transported some distance.

“This transportation can lead to a pressure drop in the piping, which equals a temperature loss. Consequently, you might find yourself in a scenario where the refrigeration plant is set at -40°C – a process demanding a substantial energy investment – but only -35°C reaches the freezer. “Such an outcome lacks efficiency, as it amounts to a 5°C loss along the way, and each degree lost is equivalent to a 3% loss in energy.”

The LVS Solution: a Recipe for Efficiency

The LVS system helps customers manage the link between each freezer and refrigeration plant in a more efficient way. With the addition of the LVS feature, any pressure drop – and consequently any temperature drop – is drastically reduced. “Instead of seeing a 5°C pressure drop, you’ll only lose 0.5°C to 1°C. Therefore, you’re almost 15% more efficient by using this feature,” adds Grundmann.

With the LVS system in place and based on 24/7 continuous operation with their recently installed line, Grundmann estimates that customers can save around €125,000 in annual energy costs thanks to the LVS. This translates to a return on investment (ROI) of less than 12 months, making it a winning proposition for any bakery focused on both cost savings and sustainability.

In the competitive world of industrial bakeries, energy efficiency is a key ingredient for success. The LVS Bakery’s story is a testament to how innovative solutions, like the LVS, can transform operations, reduce energy consumption, and lower carbon emissions. By addressing temperature loss and optimizing refrigeration systems, LVS has become an essential tool for industrial bakeries looking to enhance efficiency, save costs, and contribute to a greener future.