Efficient cleaning of a freezer is fundamentally important, not just for the obvious hygiene necessities, but also for the effective functioning of equipment. However, too often cleaning agent suppliers will sell customers detergents but leave them in the dark when it comes to their proper usage and dosage.

The result is customers can end up spending too much time and money on cleaning processes due to insufficient training, the wrong types of chemicals and volumes, or unplanned cleaning interventions. At the very least customers can face unnecessary business and environmental risks at higher costs.

This is where JBT differs. As well as having an extensive range of Clean-In-Place (CIP options) to fit all budgets, JBT provides ongoing support and training for customers to make sure cleaning processes are being carried out effectively and efficiently. Furthermore, JBT cleaning agents avoid the use of chlorine or other unsuitable chemicals, which can have a detrimentally corrosive effect on machine parts over time.

The importance of training

JBT’s Formula Clean program ensures the highest cleaning standards while preventing unnecessary wear to equipment – plus correct and safe cleaning, explains JBT Business Support Manager, Niklas Landby. “We perform and offer cleaning audits to assure the cleaning process is completed in the best way possible,” he says. “This is extremely important for food safety, and it’s important to not use unnecessarily strong or too much chemicals, which add costs and can damage your investments. Most providers offer cheaper solutions such as chlorine, which is very effective but will destroy equipment over time. We help customers optimize cleaning to make sure everything is functioning correctly.”

Landby says what makes JBT unique as a company is that we do not just supply detergents, but look at the entire operating and cleaning process. “JBT will typically set-up the concentration with the chemicals and train the customer on how the machine should be cleaned,” he continues.

“Customers reach out to JBT to get support in their cleaning process, personnel training and water temperature guidance. Too high concentrations and the associated negative environmental aspect are also a common problem, but we can help customers reach the right levels.”

Positive effects

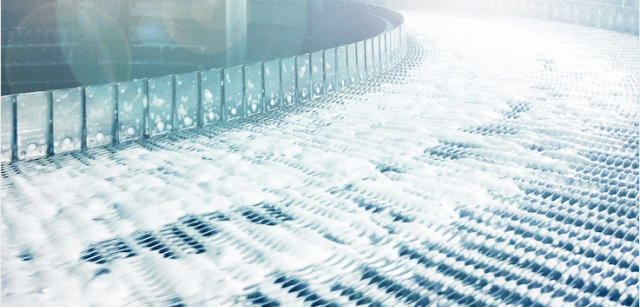

JBT’s Formula Clean detergents have been specially developed to work within food production facilities, with a range of products and applications adapted for all types of equipment operating at warm or cold temperatures. Considerations have been given to the extremes of temperatures food machinery is regularly exposed to, explains Landby, with the types of detergents used varying depending on the applications and equipment to be cleaned.

“We are seeing great results for customer plants that have already transitioned over to JBT detergents. Our customers have seen savings from decreased volumes of detergents used due to the need for fewer repeat cleans. The right detergents in the right concentrations also protect customers’ equipment at the same time,” Landby concludes.

As a key element of JBT’s commitment to customers, we have JBT OmniBlu™ which is a service platform that monitors and measures water volume and temperature, cleaning chemicals usage and concentrations and cleaning time. Moreover, OmniBlu provides customers with the reassurance that cleaning procedures are being followed and potential bacterial growth issues prevented.