Seeking a complete freezing line solution for vegetables, berries and other delicate products that increases throughput but also protects products from freezing damage?

JBT Frigoscandia together with Urtasun, the newest member of the JBT family, is now able to offer customers a unique solution that ensures product integrity, quality and flavor while also handling up to 18,000 kg per hour.

“We have managed to bring different technologies together from different sectors so we can create a single processing line for individual freezing,” explains JBT’s Director of Sales for the EMEA region, Sergio Rabadan. “Thanks to integration of Urtasun with Frigoscandia and other JBT businesses, we are now able to offer customers complete solutions whereas before customers would have to source certain systems from other providers.”

Boosting throughput

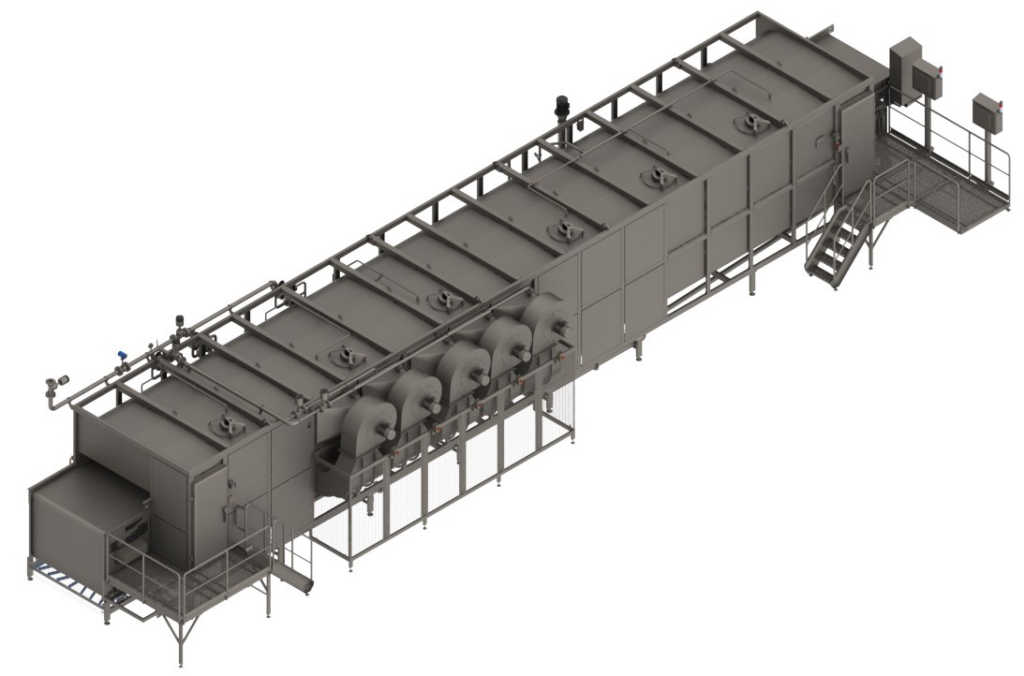

The Frigoscandia FLoFREEZE IQF freezer uses pioneering fluidization technology in the field of individual quick freezing for vegetables, fruits & berries, fish and other delicate high-end products. The freezer is able to handle up to 18 tons per hour through the FLoFREEZE series-M range using a fast-freezing airflow that can be easily modified for different kinds and sizes of products.

With the addition of the Sequential Defrost (SD) option for the FLoFREEZE series-M range, the system is not only able to handle up to 18 tons per hour, but can now run continuously for six days at full capacity before any defrost is necessary.

Given that each defrost requires production to stop and uses time, water and energy, the continuous 144 hours offered by the Sequential Defrost option allows customers to increase throughput and efficiency.

Uniquely in the freezer industry, the FLoFREEZE also includes an option for a hygenic, easy-to-clean refreezing belt, a system that pre-freezes then ‘glazes’ each item before it moves into the main unit for freezing. For delicate products, the glazing adds a layer of protection that insulates them from damage during the industrial freezing process, thus preserving quality and integrity.

The presence of the refreezing belt as a built-in feature of the FLoFREEZE avoids the need for an additional system alongside the main freezer.

Preserving product quality

With the addition of Urtasun to the JBT family, JBT´s freezing line solution has now become more complete. One of the most effective items for preserving product quality is the combination with the Urtasun Blancher, a piece of equipment that proves its worth whether canning or freezing vegetables.

JBT Urtasun Blanching Solution

Blanching is commonly used to deactivate enzymes that can adversely impact produce color, flavor and texture, while also improving vitamin retention. A further advantage offered by blanching is its ability to soften crunchy vegetables like broccoli and asparagus, making them easier to pack in bags or cans.

“In every vegetable processing line, there are two critical elements: the center of the process where the vegetables are washed and dried; followed by blanching and freezing or canning,” explains Iñigo Pardo, global sales manager for JBT Urtasun. “During blanching, we deactivate the enzyme that causes vegetables to rot. You can’t kill this enzyme, but you can deactivate it by cooking the vegetables for one or two minutes at 98C in the blancher.”

“Blanching ensures vegetables do not rot during the length of time they are frozen in a bag.”

To ensure production flows smoothly alongside the FLoFREEZE, the Urtasun Blancher can also run for up to six days continuously, Pardo adds.

Significant synergies

The next important function of the unit is to bring down the temperature of the vegetables to around 7C or 8C, before being removed from the blancher and being placed onto an Urtasun dewatering Vibratory Belt to remove any particles of water from the blancher that could create a block in the freezer.

“Every vegetable that passes through the blancher needs to go on to a freezer or filler and closer,” says Pardo. “Being part of JBT allows us to carry out this process in a joined-up way and to be able to offer a complete solution to the customer.”

In fact, Urtasun and Frigoscandia are now working together on a number of projects and have confirmed sale of their first complete solution to a major processor in Australia.

As part of this complete line, JBT is providing the customer with an Urtasun Blancher connected to a vibratory belt to remove as much water as possible, complemented with a Frigoscandia FLoFREEZE and other JBT end-of-line equipment. “From the blancher through to filling containers, it’s all JBT equipment delivering an all-in-one solution to our customers,” adds Pardo.