Looking to improve fish and poultry yields and cut down false bone-detection rates? Innospexion is a revolutionary bone-detection system that’s raising the standard for accurate identification of even the smallest bones, enabling customers to improve yield and quality across a production line.

The result of a new partnership between JBT and Denmark-based Innospexion A/S, the cutting-edge bone-detection solution is estimated to reduce false detection rates by more than 20% and is now available to JBT customers worldwide. At the same time, the system helps improve the value and sustainability of fish and poultry by boosting the yield for the same volume of products.

X-ray bone-detection systems like Innospexion also have an important food safety aspect. Finding and removing small bones from poultry and fish during processing has long been a challenge, even when checks are carried out by x-ray, due to their largely undetectable nature. But, though small, poultry and fish bones are still capable of causing abrasions, especially in children.

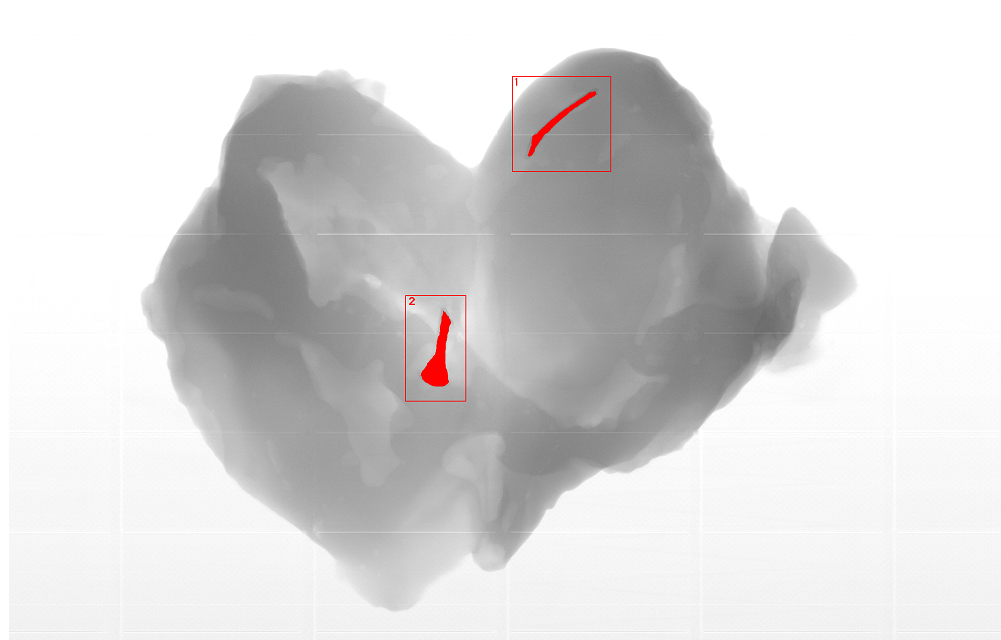

“Poultry and fish bones are lightly calcified, as a result they do not present easily in meat when X-rayed, ” explains Dino Carbone, Global Product Manager for JBT Innospexion. “Through Innospexion’s advanced source and detection technology coupled with decades of experience we can generate a very high-quality image and then accurately interpret that image to see these fine bones in contrast to the meat very well.”

“The Innospexion system is highly accurate at detecting bones at a very low false rejection rate, reducing rework and product loss at the plant.”

How does it work?

Innospexion’s unique technology allows processors to detect poultry bones down to 2 x 2 x 2mm while reducing false positive reject rates to levels substantially lower than current industry standards, driving labor reduction and higher yields.

According to Cardone, Innospexion x-ray detectors combined with its innovative software guarantees a high and reliable bone detection rate without falsely rejecting good products from the line. “What makes Innospexion different from other bone-detection systems on the market is it’s highly accurate at detecting bones it’s supposed to see and not falsely rejecting product that doesn’t have bones,” he says.

Keeping down rejection rates

“The Innospexion system detects bones at a very low false rejection rate, reducing rework and product loss at the plant,” Carbone continues.

As he explains, when an X-ray typically rejects a piece of poultry or fish, that meat is sent to the rework section of the line where workers manually cut away where they think the bone is. If that meat was falsely rejected, they still cut away where they think the bone is, which reduces yield and devalues the product.

“By reducing false rejects, we improve yield, we improve the value of the product and we also improve overall sustainability,” Carbone adds.

FIND OUT MORE or Book a Demonstration in a JBT Food Technology Center or at your site.