At JBT, we are committed to sustainability and the responsible use of resources in the food industry. We understand the vital role that the food industry plays in feeding the world’s population, and we strive to develop technologies and solutions that not only improve efficiency and yield, but also minimize waste and reduce our impact on the environment.

To this end, we offer a wide range of technologies and solutions designed to help food processors maximize yield and improve efficiency. From waterjet portioning systems and cooking and freezing equipment to post-harvest coatings and robotics, we have the equipment, digital tools, and expertise to help our customers optimize their operations and achieve their sustainability goals.

In this blog, we will take a closer look at some of the technologies and solutions that JBT has to offer for protein processors, highlighting their benefits and impacts they make to help move our customers forward to achieve higher yields. Whether you are looking to optimize protein portioning, enhance cooking yield, or improve efficiency and yield during slicing, JBT has the solution for you.

DSI – Waterjet Portioning

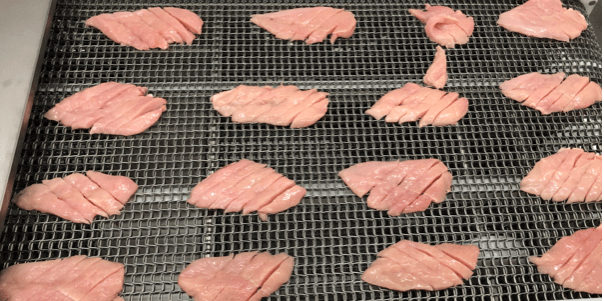

JBT’s DSI Waterjet Portioning systems are designed to optimize water usage in the food processing industry. These systems utilize precision waterjet cutting technology to cut poultry, meat, seafood and plant-based efficiently and accurately into precise portions

One of the key benefits of the Waterjet Portioning system is the vision and portion value optimization software which creates the optimal and most profitable portioning strategy that maximizes value for our customers while minimizing food waste and achieving higher yields than the traditional manual process.

In addition to its portioning optimization capabilities, the DSI-Quantum servo pump uses 60% of the power of a hydraulic pump and eliminates the inrush of spinning-up a 100 HP motor. Processors who have switched from hydraulic to the DSI system have seen energy cost savings of greater than $20,000 per year.

Optimal Cooking Process for boosting yield

The combination of JBT’s Formcook Contact Cooker and Stein Twindrum™ Spiral Oven is a powerful solution for maximizing yield and profit in the cooking of whole muscle poultry products.

By pre-cooking the product surface in the Contact Cooker prior to entry into the Twindrum Spiral Oven, processing lines can minimize cooking losses by up to 10% and increase performance by up to 20%. This not only results in a higher quality product, but also allows for longer running intervals between cleaning stops, reducing water consumption and overall operating costs.

In addition to improving yield and performance, the Contact Cooker and Twindrum Spiral Oven offer a range of other benefits. The Contact Cooker utilizes direct heat transfer to cook the product, resulting in the natural juice and fats being sealed in the product. This allows for the highest quality product and minimizes cooking losses. The Twindrum Spiral Oven, on the other hand, uses a convection cooking process that allows for faster cooking times, energy efficiency, and uniform color development.

Freezing – Crust Freezing

JBT’s Frigoscandia ADVANTEC™ Impingement Freezer technology utilizes crust freezing to improve slicing operations in the food processing industry. Crust freezing is a process that stabilizes the surface of deli products, resulting in increased throughput, yield, and hygiene when slicing.

One of the key benefits of crust freezing is the ability to reduce food waste. By stabilizing the surface of the product, slicing becomes more consistent and accurate, minimizing waste and maximizing conformity. This not only results in a higher quality product, but also increases overall yield.

In addition to its waste-reducing capabilities, the ADVANTEC Impingement Freezer offers a range of other benefits. It utilizes impingement technology to freeze products quickly and evenly, resulting in a higher quality finished product with minimal dehydration. It also has a hygienic design, with all food contact surfaces easily accessible for cleaning.

Optimize Food Processing Operations with JBT

JBT is committed to sustainability and the responsible use of resources in the food industry. We offer a wide range of technologies and solutions designed to help our customers maximize yield and improve efficiency, while minimizing waste and reducing their impact on the environment.

To support our customers in their efforts to optimize their operations, we offer a range of resources, including our Food Technology Centers and OmniBlu digital solution & service platform. These programs provide access to machine learning as well as industry experts, training, and technical support to help our customers achieve their sustainability goals.

Food Technology Centers At JBT, we are committed to helping our customers optimize their operations and achieve their sustainability goals. To support this effort, we offer a range of resources, including our Food Technology Centers (FTC’s).

Our FTC’s are located across the globe and are equipped with JBT’s equipment and staffed by experienced professionals who have access to a database of over 10,000 applications. These centers provide training, equipment demonstrations, and support for product and process development, rigorous testing of new equipment, food laboratory work, industrial and scientific symposia, and live demos at our customers’ convenience.

OmniBlu

JBT’s OmniBlu platform is a comprehensive solution for optimizing food processing operations. With its digital tools, we can monitor machine health and performance in real-time and assist in improving energy and water savings.

One of the key benefits of OmniBlu is its ability to optimize energy and water usage. By monitoring factors such as the concentrations of cleaning chemicals and the volume and temperature of cleaning water, we can provide immediate feedback and help our customers reduce waste and costs at all stages of the production process.

In addition to improving efficiency, OmniBlu helps to optimize the use of raw materials and reduce food waste. By using data analytics and machine learning, OmniBlu can identify opportunities for improvement and provide recommendations for optimizing processes.