The use of spice casings is a fast-growing trend in the world of meat processing. The taste innovation enables consumers of salami, chicken and turkey or even ham products to experience an extra layer of flavor cooked onto their favorite sandwich meats. However, spice casings can be difficult to handle, especially when it comes to maintaining a uniform layer of space on the sausage.

“A new and growing trend in deli slicing logs is spice casings, which will transfer a spice coating to the outside of the products creating a flavorful spice crust,” explains Tipper Tie’s Conrad Faust.

“And that is a significant challenge to run for most machines because the spice creates a thicker more complicated, and simply more difficult casing to run ” there’s a lot of things that must be done to make the casing run properly and not all machines can do it.”

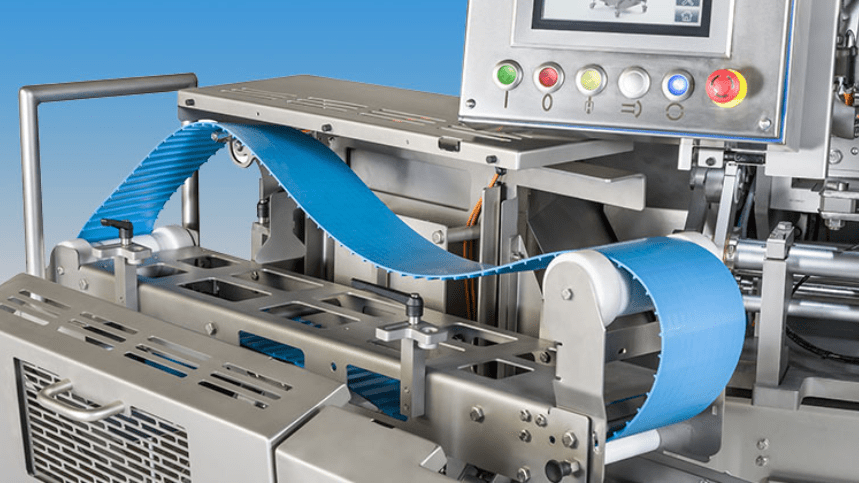

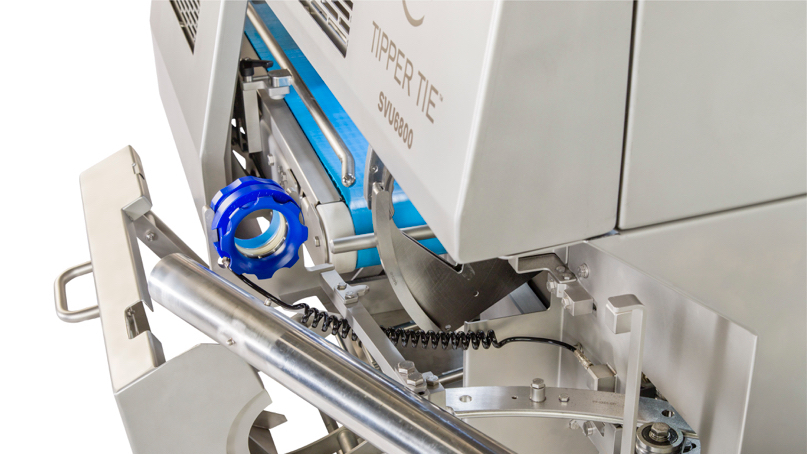

JBT TIPPER TIE?s new SVU6800, an automatic double clipper, has been developed to accommodate challenging applications like spice casings in a variety of sizes while preserving the layer of spice for effective cooking.

Replacing the previous RS4204, the SVU6800 is a step-forward in automatic double clippers, offering faster speeds combined with greater control.

“It has been designed to be better in every way,” says Faust. “Not only is it quicker, it’s also more economical to operate because we eliminated a lot of the compressed air usage and a lot more controllable because we’re using motors instead of cylinders.”

Overcoming the challenges

With the SVU 6800, Tipper Tie has not just worked hard to create a machine that can accommodate spice casings, it is further capable of handling even thicker spice casings thanks to the addition of a new function.

“We were able to test some of the leading spice casings on the market and successfully close them,” continues Faust. “These are usually plastic or fibrous casings with spices adhered to the inside. The customers stuffs salami or turkey or ham into the casing and it gets cooked – and then when they peel the casing off, the spice stays on the products, so the customer is left with this nice, very consistent, uniform spice layer on the product.

“Although delivering a tasty product, the process can also be challenging because the spice takes up a lot of space and creates a bigger challenge for the clipping machine to successfully clip and close without doing damage to the casing or stripping the spice from inside.”

Easy to live with

Tipper Tie has carried out extensive testing to show that the SVU6800 can effectively handle spice casings, even for some of the largest products. “One of the advantages of the SVU6800 is because of its speed we can run small products very quickly and still have the ability to run larger products and the control to dial in the clipping and voiding to be gentle on spice casings,” Faust adds.

“And you can go from a large, long-leg clip to a short-leg, clip for smaller products just by changing up the clip type this makes the SVU6800 a good option for customers running a variety of different products without having to do time consuming tooling changes.“