Keen to take advantage of JBT DSI’s precision waterjet portioning technologies for protein, but not yet ready to make the leap to high-yield machinery? The recently-introduced DSI 812 Compact Portioner offers an ideal solution for small-medium sized customers that features all the advantages of the system in a smaller footprint.

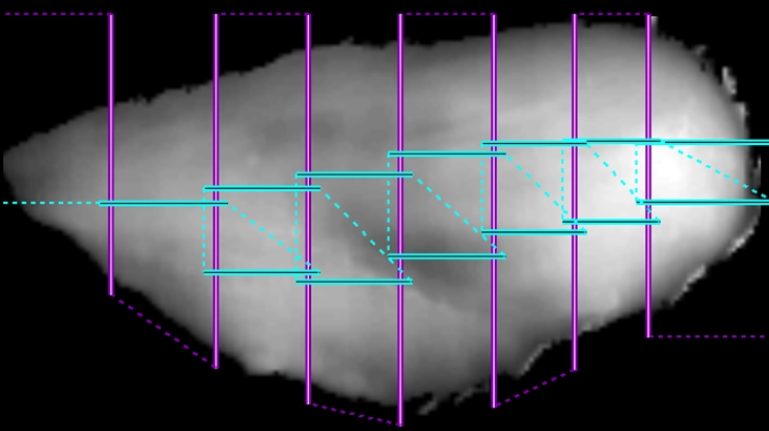

The DSI 812, which will be on display at the American Convention Of Meat Processors & Suppliers’ Exhibition from August 1-3, 2024, is a water jet portioner with an onboard pump capable of serving JBT’s small-medium sized install base, but with the same great cut strategies from DSI.

Flexible and cost-effective, the DSI 812 – which can switch from portioning portions to cubes or strips at the touch of a button – can provide both yield improvements from hand portioning and labor savings by reducing the need for skilled labor.

But more than this, the compact portioner can also help customers make some substantial savings from floorspace to utility bills.

According to Global DSI Applications Manager Tricia Harlan, the DSI 812 takes up to 70% less footprint compared to similar series waterjet portioners. Additionally, she says the onboard servo-driven waterjet pump optimizes floor space while using up to 40% less energy compared to hydraulic systems.

The JBT DSI 812: delivering complex cut strategies at the touch of a button.

From a labor perspective, Harlan says the solution has been able to reduce hand trimming resources by up to 10 positions depending on the portioning application. “With labor resources at a hard-to-find premium, the ability to redeploy highly skilled labor to other areas of the plant make the waterjet portioner a great option when looking into automation,” she says.

Since its introduction 12 months ago, DSI 812 installations have saved customers time and money portioning a wide range of products, including chicken, pork, and beef; all the more important considering the current labor challenges in many global markets.

“Since the Covid-19 pandemic in 2020, the biggest trend across the entire meat processing industry has been automation and labor,” explains Harlan. “A labor shortage has been seen in small-large processors alike. The DSI 812 has provided customers with a solution that helps reduce the need for highly-skilled labor while still providing high yield on a high quality product.”

JBT DSI will be showcasing the DSI 812 Compact Portioner at the American Convention of Meat Processors & Suppliers’ Exhibition from August 1-3, 2024.