Seeking lower false reject rates and greater accuracy when it comes to the bone-removal stage of poultry processing? Innospexion technology from JBT delivers an unprecedented level of accuracy in bone inspection that leads to significantly higher yields and less waste.

During the in-line inspection, post-deboning stage of a poultry line, chicken tenders, thighs and other cuts typically pass through an x-ray – or secondary inspection – stage to make sure no bones have been left after deboning, and it is here that unnecessary wastage is all too common.

With lower accuracy x-ray systems too much good product is rejected. Operators in product rework have to guess where imbedded bones might be located. This typically leads to significant amounts of perfectly good, high-value meat being cut away, reducing overall yield in the process.

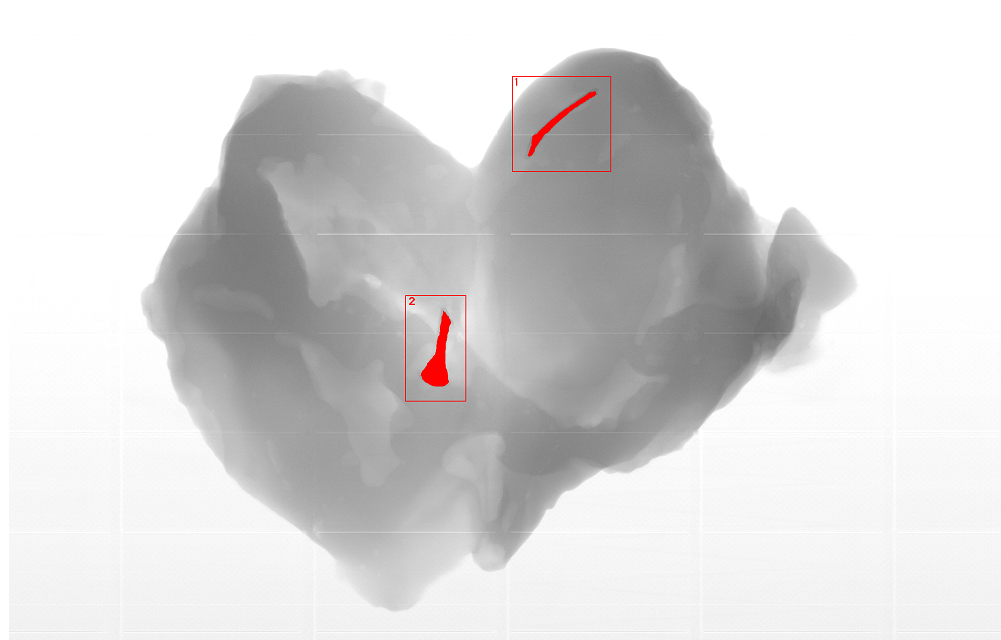

Innospexion is different. Based on a unique high image resolution, Innospexion can detect small, calcified bones in poultry and fish with very high accuracy and statistical probability. Combined with innovative software, JBT Innospexion x-ray systems guarantee a high and reliable bone detection rate with low false rejects. This system is not guessing!

So how does it work and why is it so beneficial for poultry processors?

As Dino Carbone, Division Product Manager for JBT X-ray Solutions explains, Innospexion is ideally-suited for boneless butterfly inspection, trim, nuggets, boneless leg, thigh meat and tenders. But crucially, because the innospexion system is more accurate at identifying bones, it generates substantially fewer false rejects, leading to less rework and yield loss.

“Our system is more accurate, so the false rejects are fewer and less product wasted,” he says. “Instead of guessing where the bones are like many systems today, Innospexion precisely identifies where they are located, giving customers the confidence to take poultry to rework without the risk of good product going to waste.”

In fact, Carbone estimates that Innospexion can on average reduce false rejection rates by as much as 10-20% in some instances.

But Innospexion is not only extremely precise, it is also easy-to-use and easy-to-operate, simplifying plant processes. “Because the system is highly accurate, it requires minimal adjusting and stays at optimal detection levels without the need to adjust sensitivity settings,” says Carbone.

“When systems aren’t accurate, operators have to constantly adjust the sensitivity settings leading to degraded performance. The technology behind Innospexion allows it to stay at optimal detection levels while also accounting for variations in the product and presentation.”

LEARN MORE about how JBT Innospexion can benefit poultry and fish processors