The growing convenience foods market has been accompanied by increasing customer expectations about taste and quality. Sous-vide cooking is a new trend in the food processing industry that is gaining popularity for its ability to cook food evenly and consistently, in a particularly gentle manner.

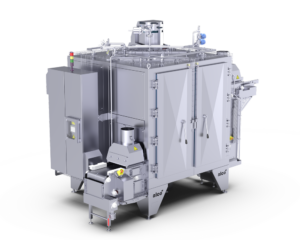

Once the preserve of professional chefs, sous-vide – which translates as “under vacuum” in French – is a cooking method involves sealing food in a vacuum-sealed bag and then cooking it in a water bath or steam oven at a consistent temperature for high-quality results. Two JBT solutions ideally suited to sous-vide cooking – the Stein TwinDrum Spiral Oven and the alco spiral oven ASH PRO – make the technique even easier and more accessible at an industrial scale.

Consistent cooking

Both spiral ovens from JBT enable you to flexibly integrate sous-vide cooking into your production, as they can be used not only for cooking or browning your products, but also as steam cooking systems.

For larger capacity operations, the Stein TwinDrum Spiral Oven, which builds on decades of JBT experience in oven engineering, delivers a uniform temperature and via an efficient two-zone spiral system. For processors moving into sous-vide, the TwinDrum’s design enables consistent cooking of food items by uniformly distributing the hot air flow across all tiers, as well as helping increase the processing yield over existing ovens.

Also available in an electric version, the oven offers spiral cooking with individual control in each zone of airspeed, temperature and humidity. Keeping the TwinDrum in optimal conditions is also straightforward thanks to low-position fans and motors for easy maintenance, plus critical components attached to the hood have been eliminated for ease of cleaning and maintenance.

Taking control

For smaller capacities, the ASH PRO employs a steam nozzle system – which can be extended with additional nozzles – that quickly surrounds products from all sides with a hot mixture of steam and air, heating them evenly as they move on the spiral conveyor. The circulation of hot steam and air begins with fans sucking up cooled air via air intake shafts at the bottom of the oven. Then, air intake nozzles deliver a targeted airflow right into the heating elements.

These two heating elements, each supported by a powerful fan, create two separate airflows, which provide even heat distribution throughout the oven. Additional baffles, mounted onto the inner walls of the spiral oven, lead to uniform air and steam distribution, even on the edges of the spiral system. The hot steam transfers its heat to the product extremely quickly and efficiently.

At the same time, control valves can be used to regulate the optimum steam supply. The ASH PRO’s digital control panel allows you to set and monitor the exact temperature you want your food to cook to, so you can be sure that it reaches the perfect doneness level and prevent overcooking.

Preserving flavor

One very important advantage of sous-vide cooking is that it can help preserve the nutrients in food and also remarkably maintain the flavor of the ingredients by cooking the food slowly and at a lower temperature. Thanks to the spiral technology, a large usable surface and immense belt length, the cooking time can be set individually; a crucial factor for the sous-vide cooking method.

By using precise temperature control and thus preventing overcooking or undercooking, JBT spiral ovens contribute to reducing food waste as well as shrinkage and in the process increasing yields by saving energy and money. The result? A more efficient production process with lower operating costs and higher quality products.

FIND OUT MORE about JBT’s Stein TwinDrum and alco ASH PRO spiral ovens